Wiring harness design is a crucial aspect of electrical engineering, involving the systematic organization and protection of wires and cables within a vehicle or machine. Effective design ensures reliable power distribution and signal transmission, preventing shorts and other electrical failures. A well-designed harness also simplifies maintenance and reduces the risk of errors during assembly. The process demands careful consideration of environmental factors, space constraints, and regulatory requirements. Ultimately, robust wiring harness design contributes significantly to the overall performance and safety of the system it supports.

The complexity of modern electrical systems necessitates sophisticated wiring harness design processes. These designs must account for the increasing number of electronic components and the demand for greater efficiency. This involves selecting appropriate wire gauges, insulation materials, and connectors. Furthermore, careful routing and securement of wires are essential to minimize electromagnetic interference (EMI) and vibration-induced damage.

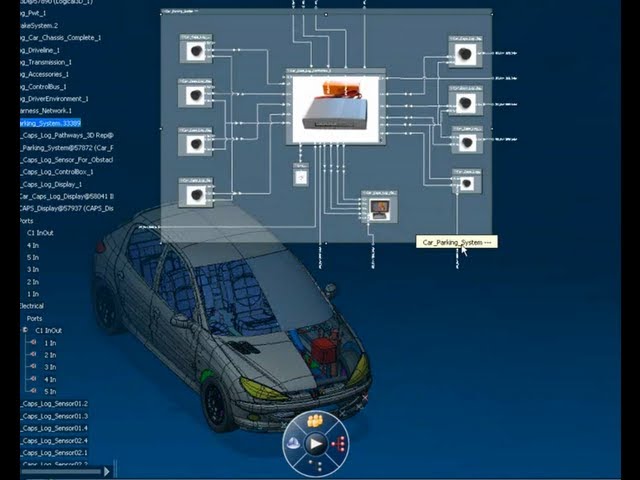

Effective wiring harness design minimizes weight and space requirements, both critical considerations in industries like aerospace and automotive. Software tools play a vital role in the design process, allowing engineers to simulate performance and optimize layouts. Collaboration between design engineers, manufacturing teams, and quality control personnel is also crucial for a successful outcome.

The Core Challenges in Wiring Harness Design

The realm of wiring harness design is often a focal point in engineering circles, sparking discussions on forums and social media, reflecting its significant impact across various industries. These discussions frequently arise due to the intricacies involved in balancing performance, reliability, and cost-effectiveness. Design engineers are constantly seeking innovative solutions to meet increasingly stringent requirements for safety and efficiency. The development of new materials and manufacturing techniques is driving ongoing advancements in the field.

One common area of discussion revolves around minimizing the weight and size of wiring harnesses. This is particularly important in applications where space and weight are at a premium, such as in aircraft and electric vehicles. Another challenge is ensuring the harness can withstand harsh environmental conditions, including extreme temperatures, humidity, and vibration. Software tools and simulation techniques have become indispensable in addressing these design complexities.

The integration of advanced functionalities, such as data communication and power distribution, also adds to the design challenge. Ensuring compatibility and avoiding interference between different systems requires careful planning and testing. Moreover, the growing focus on sustainability is driving the demand for more environmentally friendly materials and manufacturing processes in wiring harness design. Collaboration between design, manufacturing, and quality control teams is essential to overcome these challenges and deliver reliable and cost-effective solutions.

Optimizing Wiring Harness Design for Efficiency

The optimization of wiring harness design is critical for achieving both performance and cost-effectiveness. This involves carefully selecting materials, designing efficient layouts, and implementing robust manufacturing processes. The goal is to create a harness that meets all performance requirements while minimizing weight, size, and cost. Furthermore, the design must also consider factors such as ease of installation and maintenance.

Frequently Asked Questions About Wiring Harness Design

Addressing common queries regarding wiring harness design is vital for fostering a deeper understanding of its principles and applications. These FAQs aim to clarify fundamental aspects, provide insights into best practices, and offer guidance for overcoming common challenges. By addressing these questions, it is possible to promote a more informed approach to design, manufacturing, and maintenance. This ultimately leads to improved performance, reliability, and safety in electrical systems.

What are the key considerations when selecting wire gauges for a wiring harness?

Selecting the appropriate wire gauge involves considering the current carrying capacity, voltage drop, and mechanical strength required for each circuit. Thicker wires offer lower resistance and can handle higher currents but are also heavier and more expensive. The wire gauge should be chosen to minimize voltage drop and prevent overheating while also considering space and weight constraints. It’s critical to consult relevant standards and guidelines to ensure the selected wire gauge meets safety and performance requirements.

How can electromagnetic interference (EMI) be minimized in a wiring harness design?

Minimizing EMI involves several strategies, including shielding wires, using twisted pair configurations, and grounding the harness properly. Shielded wires help contain electromagnetic radiation, while twisted pairs reduce the loop area and cancel out common-mode noise. Effective grounding provides a low-impedance path for stray currents, preventing them from interfering with other circuits. Careful routing of wires away from noise sources can also help minimize EMI. Additionally, using appropriate connectors and ensuring proper termination techniques are crucial for maintaining the integrity of the shield.

What software tools are commonly used in wiring harness design?

Several software tools are available to aid in the design and simulation of wiring harnesses. These tools can help engineers create detailed 3D models, optimize wire routing, and analyze electrical performance. Common software packages include those offered by Mentor Graphics, Zuken, and E3 series. These tools often incorporate features such as automatic wire routing, bill of materials generation, and design rule checking. Using these tools can significantly improve the efficiency and accuracy of the design process.

How can the weight of a wiring harness be minimized?

Minimizing weight involves selecting lightweight materials, optimizing wire lengths, and using efficient connector designs. Aluminum wires can be used in place of copper in some applications to reduce weight. Minimizing the length of each wire and using smaller gauge wires where appropriate can also contribute to weight reduction. Efficient connector designs, such as those made from lightweight plastics, can further reduce the overall weight of the harness. Careful attention to routing and securement methods can also minimize the amount of material needed.

What are the best practices for documenting a wiring harness design?

Comprehensive documentation is essential for effective communication and maintenance of a wiring harness design. This documentation should include detailed schematics, wiring diagrams, and bill of materials. The schematics should clearly show the connections between all components, while the wiring diagrams should illustrate the physical layout of the harness. The bill of materials should list all the components used in the harness, including wire gauges, connectors, and terminals. The documentation should also include any special instructions or warnings related to installation or maintenance.

How does one ensure a wiring harness can withstand harsh environmental conditions?

Ensuring a wiring harness can withstand harsh environmental conditions involves selecting appropriate materials and implementing robust protection measures. Wires and connectors should be rated for the expected temperature range, humidity levels, and exposure to chemicals. Protection measures can include using abrasion-resistant sleeving, waterproof connectors, and strain relief devices. Additionally, the harness should be designed to minimize exposure to vibration and mechanical stress. Regular inspection and maintenance can also help identify and address potential issues before they lead to failures.

What are the key safety considerations in wiring harness design?

Safety is paramount in wiring harness design. Factors include overcurrent protection (fuses and circuit breakers), proper grounding, and insulation to prevent electrical shock. Selection of materials rated to withstand high temperatures is vital for preventing fires. Clear labeling is essential to prevent wiring errors during installation and maintenance. Compliance with industry standards like UL and IEC ensures the design meets accepted safety benchmarks. Routine testing and inspection are required to verify the wiring harness’s integrity and safety throughout its lifespan.

The increasing demand for complex electrical systems in various industries necessitates a robust approach to wiring harness design. The design process must consider factors such as performance, reliability, cost, and safety. A well-designed harness can significantly improve the overall efficiency and longevity of the system it supports. Moreover, proper documentation and testing are essential for ensuring the harness meets all required specifications.

Effective wiring harness design also involves collaboration between different engineering disciplines, including electrical, mechanical, and manufacturing. This collaborative approach ensures that all aspects of the design are carefully considered and optimized. Furthermore, continuous improvement and innovation are crucial for keeping pace with evolving technologies and customer needs. By embracing new materials, manufacturing techniques, and design methodologies, engineers can create harnesses that are lighter, more efficient, and more reliable.

Key Aspects of Wiring Harness Design

Focusing on the essential aspects of wiring harness design is paramount. As a noun, “wiring harness design” suggests a multifaceted subject. Therefore, key aspects include material selection, routing optimization, and regulatory compliance. These dimensions are critical for ensuring a durable, efficient, and safe wiring solution. Proper planning and execution across these aspects are essential for a successful outcome.

Material Selection

Material selection involves the choice of wire insulation, connector housings, and other components used in the harness. The chosen materials must be able to withstand the environmental conditions to which the harness will be exposed, including temperature extremes, humidity, and exposure to chemicals. The selection of wire gauge is also critical, as it determines the current carrying capacity of the harness. Furthermore, the materials must be compatible with each other to prevent corrosion or other forms of degradation. Ultimately, the right material selection ensures the harness maintains its performance and reliability over its lifespan.

Routing Optimization

Routing optimization refers to the process of determining the most efficient and effective path for the wires within the harness. This involves minimizing wire lengths, avoiding sharp bends, and ensuring adequate clearance between wires and other components. Optimized routing helps reduce weight, minimize voltage drop, and improve the overall performance of the harness. Simulation tools can be used to analyze different routing options and identify the best solution. Proper routing also facilitates easier installation and maintenance of the harness.

Regulatory Compliance

Regulatory compliance refers to the need to meet all applicable safety and performance standards. This can include standards set by organizations such as UL, IEC, and SAE. Compliance ensures that the harness meets minimum requirements for safety, reliability, and environmental impact. Testing and certification are often required to demonstrate compliance. Failure to comply with these regulations can result in legal penalties and damage to reputation. Therefore, it is essential to carefully consider all relevant regulations during the design process.

Detailed discussion of these key aspects, through examples, connections, or linkage to the main topic provides a comprehensive view of factors that influence and make-up an effective wiring harness.

The intricacies of wiring harness design highlight the necessity of a comprehensive and detail-oriented approach. This is critical not only for guaranteeing optimal performance but also for upholding the highest standards of safety and regulatory compliance. Thorough documentation and rigorous testing are indispensable in verifying the integrity and dependability of the final product. By meticulously managing these facets, engineers can ensure that the wiring harness meets all the necessary requirements and performs effectively throughout its intended lifespan.

Essential Tips for Effective Wiring Harness Design

Achieving excellence in wiring harness design requires careful attention to detail and adherence to best practices. The following tips provide guidance on key aspects of the design process, from material selection to testing and documentation. By implementing these tips, engineers can enhance the reliability, performance, and safety of their wiring harnesses. A systematic approach is crucial for delivering high-quality designs that meet customer expectations.

Effective wiring harness design involves a combination of technical expertise, practical experience, and a commitment to continuous improvement. These tips are intended to serve as a valuable resource for engineers seeking to optimize their designs and stay ahead of the curve. By incorporating these guidelines into their workflow, engineers can produce harnesses that are more efficient, durable, and cost-effective.

-

Use a 3D CAD Software

Employing 3D CAD software is essential for visualizing and designing complex wiring harnesses. These tools allow engineers to create detailed models, optimize wire routing, and identify potential interference issues. 3D CAD software also facilitates collaboration between design, manufacturing, and assembly teams. The ability to simulate performance and check for design rule violations can significantly improve the accuracy and efficiency of the design process.

-

Select the Right Materials

Choosing appropriate materials is crucial for ensuring the durability and reliability of the wiring harness. Consider factors such as temperature range, humidity levels, exposure to chemicals, and mechanical stress. Select wires, connectors, and other components that are rated for the intended environment. Using high-quality materials can prevent premature failures and extend the lifespan of the harness.

-

Optimize Wire Routing

Efficient wire routing is key to minimizing weight, reducing voltage drop, and preventing EMI. Keep wire lengths as short as possible and avoid sharp bends. Use proper securement methods to prevent chafing and vibration-induced damage. Consider the proximity of wires to heat sources and other potential hazards. Simulation tools can help optimize wire routing and identify potential issues early in the design process.

-

Implement Proper Shielding

Shielding is essential for minimizing EMI and ensuring the integrity of sensitive signals. Use shielded wires and connectors in areas where EMI is a concern. Properly ground the shielding to provide a low-impedance path for stray currents. Consider using ferrite cores or other filtering techniques to further reduce EMI. Testing and validation are crucial for verifying the effectiveness of the shielding.

-

Design for Manufacturability

Consider the manufacturability of the harness during the design process. Simplify the design as much as possible to reduce assembly time and cost. Use standard components and avoid overly complex or intricate designs. Consult with manufacturing engineers to identify potential challenges and optimize the design for efficient production. Properly documented designs and clear assembly instructions are essential for successful manufacturing.

-

Ensure Adequate Strain Relief

Strain relief is critical for preventing damage to wires and connectors at termination points. Use appropriate strain relief devices to support the wires and prevent them from being pulled or bent excessively. Consider the weight of the harness and the potential for movement or vibration. Proper strain relief can significantly extend the lifespan of the harness and prevent costly failures.

-

Use Proper Labeling and Documentation

Clear and accurate labeling and documentation are essential for easy installation, maintenance, and troubleshooting. Label each wire and connector with a unique identifier. Create detailed wiring diagrams and schematics that clearly show the connections between all components. Include a bill of materials that lists all the components used in the harness. Proper labeling and documentation can save time and reduce errors during installation and maintenance.

-

Test and Validate the Design

Thorough testing and validation are crucial for verifying the performance and reliability of the wiring harness. Conduct electrical tests to verify continuity, insulation resistance, and voltage drop. Perform mechanical tests to evaluate the harness’s ability to withstand vibration, shock, and temperature extremes. Use simulation tools to predict performance and identify potential issues. Proper testing and validation can help identify and correct design flaws before they lead to failures in the field.

The comprehensive nature of wiring harness design requires a blend of knowledge, precision, and forward-thinking strategy. The ability to adapt to the evolving demands of modern technology is vital. Furthermore, by continuously refining design methods and integrating feedback from manufacturing and field operations, engineers can achieve superior outcomes.

Embracing innovative solutions and staying abreast of the latest advancements in materials and manufacturing techniques are essential for maintaining a competitive edge. Proactive engagement with industry standards and regulatory requirements further ensures that designs are not only efficient and reliable but also compliant and safe. As the demand for more complex and sophisticated electrical systems continues to grow, the role of skilled and knowledgeable wiring harness designers will only become more critical.

In conclusion, robust wiring harness design is paramount for electrical system integrity and longevity.

Youtube Video: