A tail light wiring harness is a crucial part of a vehicle’s electrical system that supplies power to the rear lights, including taillights, brake lights, and turn signals. It consists of a bundle of wires, connectors, and terminals that are arranged to provide electrical power from the vehicle’s battery to the lighting components at the rear of the vehicle.

Properly functioning tail light wiring harnesses are essential for road safety, ensuring that a vehicle’s rear lights are visible to other drivers, especially during nighttime or inclement weather conditions. Faulty wiring can lead to malfunctioning lights, increasing the risk of accidents. Regular inspection and maintenance of tail light wiring harnesses are recommended to prevent any issues and ensure optimal performance.

This article will delve deeper into the components, functions, and maintenance aspects of tail light wiring harnesses, providing valuable insights into their significance for vehicle safety and overall driving experience.

Tail Light Wiring Harness

A tail light wiring harness is a critical component of a vehicle’s electrical system, ensuring the proper functioning of rear lights for safety and communication on the road. Here are seven key aspects to consider:

- Connectivity: Connects electrical power from the battery to the rear lighting components.

- Functionality: Enables the operation of taillights, brake lights, and turn signals.

- Safety: Ensures visibility of the vehicle to other drivers, preventing accidents.

- Customization: Can be modified for specific vehicle models and lighting configurations.

- Durability: Designed to withstand harsh environmental conditions and vibrations.

- Inspection: Regular checks are crucial to identify and address any issues.

- Maintenance: Proper maintenance extends the lifespan of the wiring harness and lighting system.

These aspects highlight the significance of tail light wiring harnesses in ensuring the safety and functionality of a vehicle’s rear lighting system. Regular inspection, maintenance, and occasional customization can contribute to the overall driving experience and enhance road safety for all.

Connectivity

Within the context of a tail light wiring harness, the connectivity aspect plays a critical role in establishing a reliable electrical connection between the vehicle’s battery and the rear lighting components, such as taillights, brake lights, and turn signals. This connection is essential for ensuring that these lighting components function properly, enabling drivers to communicate their intentions clearly to other road users and enhancing overall driving safety.

- Electrical Power Distribution: The wiring harness acts as a conduit for distributing electrical power from the battery to each rear lighting component. It ensures that each light receives the necessary voltage and current to illuminate when activated by the driver.

- Circuit Protection: The wiring harness incorporates fuses or circuit breakers to protect the electrical system from overloads or short circuits. These protective devices prevent damage to the wiring and lighting components in the event of electrical faults.

- Signal Transmission: The wiring harness facilitates the transmission of electrical signals from the vehicle’s lighting switches and sensors to the respective rear lighting components. This enables drivers to control the lights and communicate their intentions to other vehicles on the road.

- Customization and Modifications: The connectivity aspect of the wiring harness allows for customization and modifications to accommodate different vehicle models and specific lighting configurations. This flexibility supports the integration of additional lighting features or upgrades to enhance the vehicle’s safety and aesthetics.

In summary, the connectivity facet of a tail light wiring harness is crucial for establishing a reliable electrical connection between the battery and rear lighting components. It ensures proper functioning of the lighting system, enhances driving safety, and provides flexibility for customization and modifications.

Functionality

Within the context of a tail light wiring harness, the functionality aspect centers around its critical role in enabling the proper operation of the vehicle’s rear lighting system. This system plays a vital role in ensuring the safety and functionality of a vehicle on the road.

- Tail Light Operation: The wiring harness provides the necessary electrical connections to power the taillights, ensuring that they illuminate when the vehicle’s headlights are turned on. This helps make the vehicle visible to other drivers, especially during nighttime or low-visibility conditions.

- Brake Light Activation: The wiring harness facilitates the activation of brake lights when the driver presses the brake pedal. These lights signal to following vehicles that the vehicle is slowing down or stopping, preventing potential rear-end collisions.

- Turn Signal Operation: The wiring harness enables the operation of turn signals, which are essential for communicating the vehicle’s intended direction changes to other drivers. When the driver activates the turn signal lever, the corresponding turn signal lights (front and rear) illuminate, indicating the vehicle’s intended maneuver.

- Customization and Modifications: The functionality aspect of the wiring harness supports customization and modifications to accommodate specific lighting configurations or additional lighting features. This flexibility allows for upgrades or enhancements to the rear lighting system, improving visibility and safety.

In summary, the functionality aspect of a tail light wiring harness is crucial for ensuring the proper operation of taillights, brake lights, and turn signals. These lighting components are essential for effective communication with other drivers, enhancing overall driving safety, and complying with legal requirements.

Safety

In the context of a tail light wiring harness, the safety aspect holds paramount importance as it directly relates to the visibility and communication of a vehicle’s intentions on the road. A properly functioning wiring harness ensures that the rear lighting system operates as intended, enabling other drivers to clearly see and understand the vehicle’s actions, thereby preventing potential accidents.

- Enhanced Visibility: A tail light wiring harness provides electrical power to the taillights, brake lights, and turn signals, ensuring that these lights illuminate when activated. This enhanced visibility makes the vehicle more conspicuous to other drivers, especially during nighttime or inclement weather conditions, reducing the risk of rear-end collisions and other accidents.

- Clear Communication: The wiring harness facilitates the transmission of electrical signals from the vehicle’s lighting switches to the respective rear lighting components. This enables drivers to communicate their intentions clearly and effectively to other road users, such as when braking or changing lanes. Proper communication reduces the likelihood of misunderstandings and accidents.

- Legal Compliance: In many jurisdictions, it is a legal requirement for vehicles to have functioning rear lighting systems. The tail light wiring harness plays a crucial role in ensuring compliance with these regulations, promoting road safety and avoiding potential legal penalties.

- Accident Prevention: By ensuring the proper operation of rear lighting components, a tail light wiring harness contributes significantly to accident prevention. It enhances the visibility of the vehicle, enables clear communication of intentions, and complies with legal requirements, all of which work together to reduce the risk of accidents on the road.

In summary, the safety aspect of a tail light wiring harness is inextricably linked to its role in ensuring the visibility of the vehicle to other drivers, preventing accidents, and promoting overall road safety. A properly functioning wiring harness is essential for effective communication, legal compliance, and the well-being of all road users.

Customization

The aspect of customization in tail light wiring harnesses holds significant importance due to the variations in vehicle models and lighting configurations. This adaptability allows for tailored modifications to accommodate specific requirements and preferences.

Firstly, different vehicle models often have unique rear lighting designs and electrical systems. The wiring harness can be customized to match the specific electrical architecture and connector types of each vehicle, ensuring compatibility and proper functioning of the rear lighting components.

Secondly, customization enables the integration of specific lighting configurations, such as custom taillight designs or additional lighting features like reverse lights or fog lights. Modifying the wiring harness allows for the incorporation of these additional lighting components, enhancing the vehicle’s functionality and aesthetic appeal.

Understanding the connection between customization and tail light wiring harnesses is crucial for several reasons. Firstly, it empowers vehicle owners and enthusiasts to personalize their vehicles and tailor the lighting system to their specific needs and preferences. Secondly, it supports the adaptation of wiring harnesses to accommodate the evolving lighting technologies and designs in the automotive industry.

In conclusion, the customization aspect of tail light wiring harnesses plays a vital role in accommodating diverse vehicle models and lighting configurations. It enables tailored modifications, enhances functionality, and supports the integration of custom lighting features, contributing to the overall driving experience and vehicle aesthetics.

Durability

In the context of a tail light wiring harness, durability plays a pivotal role in ensuring the longevity and reliability of the vehicle’s rear lighting system. This aspect directly relates to the challenging environmental conditions and vibrations that a tail light wiring harness encounters during its service life.

The tail light wiring harness is subjected to extreme temperatures, moisture, and road vibrations, which can take a toll on its components over time. To withstand these harsh conditions, the wiring harness is meticulously designed and constructed using durable materials and robust construction techniques.

The use of high-quality wires, connectors, and insulation materials ensures that the wiring harness can endure exposure to moisture, heat, and chemicals without compromising its electrical integrity. Additionally, the harness is often protected by a durable outer sheath or conduit, safeguarding it from physical damage caused by road debris, vibrations, and accidental impacts.

Understanding the importance of durability in tail light wiring harnesses is crucial for several reasons. Firstly, it helps ensure the longevity of the rear lighting system, reducing the need for frequent repairs or replacements. Secondly, a durable wiring harness contributes to the overall safety of the vehicle by ensuring that the rear lights remain functional even in adverse conditions, enhancing visibility and communication with other road users.

In conclusion, the durability aspect of a tail light wiring harness is essential for maintaining the reliability and longevity of the vehicle’s rear lighting system. By withstanding harsh environmental conditions and vibrations, the wiring harness ensures that the taillights, brake lights, and turn signals continue to function effectively, contributing to road safety and overall driving experience.

Inspection

Regular inspection of the tail light wiring harness is paramount to ensure the proper functioning and longevity of a vehicle’s rear lighting system. This proactive approach allows for the early detection and rectification of any potential issues, preventing minor problems from escalating into more significant and costly repairs.

The harsh operating environment that a tail light wiring harness encounters, characterized by exposure to moisture, extreme temperatures, road vibrations, and potential physical damage, necessitates regular inspection to maintain its integrity. Over time, these factors can lead to wear and tear, corrosion, loose connections, or damage to the wires or connectors, compromising the electrical performance of the rear lighting system.

By conducting regular inspections, vehicle owners and mechanics can proactively identify and address any issues before they lead to more severe problems. This may involve visual of the wiring harness for any signs of damage or corrosion, checking the tightness of electrical connections, and testing the functionality of the rear lights, including taillights, brake lights, and turn signals.

The practical significance of regular inspection lies in its ability to prevent potential safety hazards and costly repairs. A properly functioning tail light wiring harness ensures that the vehicle’s rear lights are visible to other road users, enabling effective communication of braking intentions, lane changes, and overall vehicle presence, especially during nighttime or inclement weather conditions.

In summary, regular inspection of the tail light wiring harness is a crucial aspect of maintaining a reliable and safe rear lighting system. Proactive identification and resolution of any issues contribute to the longevity of the wiring harness, enhance road safety, and provide peace of mind to vehicle owners.

Maintenance

Proper maintenance of a tail light wiring harness is crucial for ensuring its optimal performance and longevity. This involves regular inspections, cleaning, and addressing any potential issues promptly. By adhering to a proactive maintenance schedule, vehicle owners can significantly extend the lifespan of both the wiring harness and the entire rear lighting system.

The tail light wiring harness is exposed to harsh environmental conditions, including moisture, extreme temperatures, road vibrations, and potential physical damage. Over time, these factors can lead to wear and tear, corrosion, loose connections, or damage to the wires or connectors, compromising the electrical performance of the rear lighting system. Regular maintenance helps to mitigate these effects and prevent minor problems from escalating into more significant and costly repairs.

For instance, regular cleaning of the wiring harness can remove dirt, debris, and moisture that may accumulate over time. This helps prevent corrosion and ensures that electrical connections remain secure. Additionally, periodic inspection allows for the early detection of any damage or loose connections, enabling prompt repair or replacement before they lead to more severe issues.

By understanding the importance of proper maintenance and adhering to a regular maintenance schedule, vehicle owners can proactively extend the lifespan of their tail light wiring harness and rear lighting system. This not only enhances road safety by ensuring that the vehicle’s rear lights are functioning correctly but also saves on costly repairs and replacements in the long run.

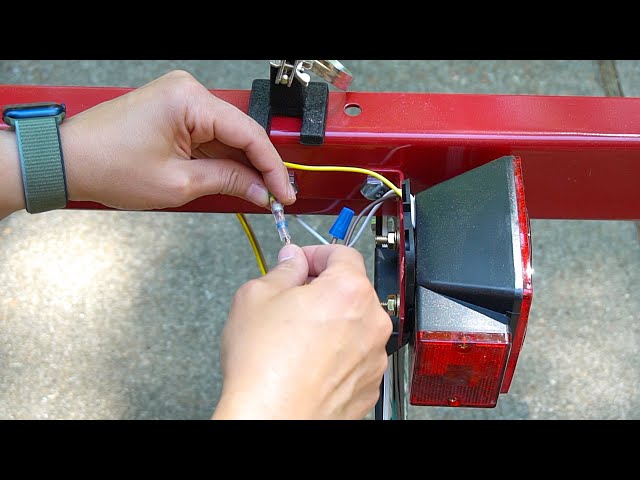

Creating a Tail Light Wiring Harness

A tail light wiring harness is a crucial component of a vehicle’s electrical system, ensuring the proper functioning of rear lights for safety and communication on the road. Creating a tail light wiring harness requires careful planning and execution, and using charts and diagrams can significantly simplify the process.

Here are three common types of charts and diagrams used for creating tail light wiring harnesses, along with their respective steps and guidelines:

-

Electrical Schematic:

- Identify the electrical components that will be connected by the wiring harness, such as taillights, brake lights, and turn signals.

- Draw a diagram representing the electrical connections between these components using standard electrical symbols.

- Label the wires with their corresponding colors and functions.

-

Wiring Diagram:

- Use a more detailed diagram to show the physical layout of the wiring harness.

- Indicate the routing of the wires, the location of connectors, and the mounting points for the wiring harness.

- Specify the wire gauges and types to be used.

-

Connector Diagram:

- Create a separate diagram for each type of connector used in the wiring harness.

- Show the pinout of each connector, indicating the wire colors and functions.

- Include any additional details, such as the connector type and manufacturer’s specifications.

By following these steps and utilizing appropriate charts and diagrams, you can effectively design and create a tail light wiring harness that meets the specific requirements of your vehicle and ensures the proper functioning of your rear lighting system.

Frequently Asked Questions about Tail Light Wiring Harnesses

Tail light wiring harnesses play a crucial role in ensuring the proper functioning of a vehicle’s rear lighting system. Here are answers to some frequently asked questions about tail light wiring harnesses:

Question 1: What is the purpose of a tail light wiring harness?

A tail light wiring harness provides electrical power to the rear lighting components of a vehicle, including taillights, brake lights, and turn signals. It ensures that these lights illuminate when activated, enabling the vehicle to be visible to other drivers and enhancing overall driving safety.

Question 2: What are the signs of a faulty tail light wiring harness?

Common signs of a faulty tail light wiring harness include malfunctioning rear lights, such as dim or flickering lights, lights that do not illuminate, or intermittent operation. Additionally, physical damage to the wiring harness, such as cuts or breaks, can also indicate a fault.

Question 3: How often should a tail light wiring harness be inspected?

Regular inspection of the tail light wiring harness is recommended to identify and address any potential issues early on. Inspections should be conducted periodically, especially before long trips or in harsh weather conditions that can affect the wiring harness’s performance.

Question 4: Can I repair a tail light wiring harness myself?

While it is possible to repair a tail light wiring harness with the necessary electrical skills and tools, it is generally recommended to seek professional assistance from a qualified mechanic. Improper repairs can lead to further electrical issues or safety hazards.

Question 5: What are the consequences of a faulty tail light wiring harness?

A faulty tail light wiring harness can result in malfunctioning rear lights, compromising the vehicle’s visibility to other drivers. This can increase the risk of accidents, especially during nighttime or inclement weather conditions when rear lights are essential for safe driving.

Question 6: How can I extend the lifespan of my tail light wiring harness?

Regular inspections, proper maintenance, and protection from harsh environmental factors can help extend the lifespan of a tail light wiring harness. Regular cleaning, addressing any loose connections or damage promptly, and using protective measures like wire loom or conduit can contribute to the longevity of the wiring harness.

Understanding these frequently asked questions can help you maintain a properly functioning tail light wiring harness, ensuring the safety and reliability of your vehicle’s rear lighting system.

Additional resources:

- Vehicle Maintenance Guide: Tail Light Wiring Harness Inspection and Replacement

- Automotive Electrical Systems: Troubleshooting Tail Light Wiring Harness Issues

Conclusion

Throughout this comprehensive exploration of tail light wiring harnesses, we have delved into their crucial role in ensuring the proper functioning of a vehicle’s rear lighting system. These harnesses provide electrical power to taillights, brake lights, and turn signals, enabling drivers to communicate their intentions clearly and enhancing overall driving safety.

Regular inspection, maintenance, and occasional customization of tail light wiring harnesses are essential for maintaining their performance and longevity. By adhering to recommended maintenance schedules and addressing any issues promptly, vehicle owners can extend the lifespan of their wiring harnesses and rear lighting systems, contributing to safer roads for all. Additionally, the use of charts and diagrams during the creation process can simplify the design and installation of tail light wiring harnesses, ensuring optimal functionality and reliability.

In conclusion, tail light wiring harnesses are critical components that play a vital role in vehicle safety. By understanding their functions, importance, and proper maintenance practices, we can contribute to safer driving experiences and enhance the overall reliability of our vehicles.

Youtube Video: