The Curtis Sno Pro 3000 wiring harness is a crucial component for the reliable operation of snowplows, facilitating the electrical connections necessary for plow functions. This specialized harness ensures that all electrical components, from the plow lights to the hydraulic pump, receive the correct power and signals for proper operation. Without a properly functioning wiring harness, the snowplow may experience intermittent failures or complete shutdown, rendering it useless during critical snow removal operations. Choosing the correct harness is imperative for ensuring compatibility and longevity. The integrity of this wiring system directly influences the efficiency and safety of snow removal tasks.

A replacement or upgrade of the Curtis Sno Pro 3000 wiring harness may become necessary due to wear and tear, corrosion, or damage sustained from exposure to harsh weather conditions. Understanding the specific requirements of the plow and the electrical system is vital when selecting a new harness. Factors such as wire gauge, connector type, and overall length must be carefully considered to ensure a seamless integration with the existing electrical infrastructure. Proper installation is paramount to avoid electrical shorts or malfunctions, which can lead to costly repairs and downtime.

Understanding the Curtis Sno Pro 3000 Wiring Harness Functionality

The Curtis Sno Pro 3000 wiring harness is frequently discussed among snowplow operators and maintenance professionals due to its essential role in plow functionality. Concerns often revolve around the durability and reliability of the harness in challenging winter conditions. Discussions frequently arise regarding troubleshooting common wiring issues, such as diagnosing faulty connections or identifying damaged wires. The proper maintenance and care of the wiring harness are also topics of interest, as preventative measures can significantly extend the lifespan of the component.

Within online forums and professional networks, users often share experiences and tips on how to best protect the Curtis Sno Pro 3000 wiring harness from environmental factors. This includes employing dielectric grease to prevent corrosion, securing the harness to avoid chafing against other components, and periodically inspecting the wires for signs of wear. The impact of improper installation on the performance of the plow is also a recurring theme. These dialogues highlight the importance of having a thorough understanding of the harness and its role within the overall snowplow system.

Furthermore, the availability and compatibility of aftermarket or replacement parts for the Curtis Sno Pro 3000 wiring harness is a common point of discussion. Snowplow operators often seek recommendations for reliable suppliers and compare the quality and pricing of different options. The long-term cost-effectiveness of investing in a high-quality harness is another aspect that is frequently debated, given the potential savings on maintenance and repairs over time.

Inspecting the Curtis Sno Pro 3000 Wiring Harness

The inspection of a Curtis Sno Pro 3000 wiring harness involves several steps to ensure it is in good working condition and to identify any potential problems. A thorough visual examination is the first step, looking for any signs of physical damage such as cuts, abrasions, or cracks in the insulation. Checking the connectors for corrosion or loose connections is also crucial, as these can lead to electrical issues. Testing the continuity of the wires with a multimeter can help identify any breaks in the circuit.

Step 1: Visual Inspection

Begin by visually inspecting the entire length of the wiring harness. Look for any signs of physical damage, such as cuts, abrasions, or cracks in the insulation. Pay close attention to areas where the harness is exposed to friction or stress, such as where it passes through the frame of the snowplow. Also, look for any signs of rodent damage.

Step 2: Connector Check

Examine all connectors for signs of corrosion or loose connections. Corrosion can appear as a greenish or whitish buildup on the metal contacts. Loose connections can cause intermittent electrical problems. Use a wire brush or electrical contact cleaner to remove any corrosion. Ensure that the connectors are securely fastened and that the locking mechanisms are functioning properly.

Step 3: Continuity Testing

Use a multimeter to test the continuity of each wire in the harness. This will help identify any breaks in the circuit. Set the multimeter to the continuity setting and connect the probes to the ends of each wire. If the multimeter shows continuity, the wire is intact. If the multimeter does not show continuity, the wire is broken and needs to be replaced.

Step 4: Voltage Testing

With the snowplow connected to the power source, use a multimeter to test the voltage at various points in the wiring harness. This will help identify any voltage drops or other electrical problems. Compare the readings to the manufacturer’s specifications to ensure that the wiring harness is operating within the correct parameters.

Frequently Asked Questions About the Curtis Sno Pro 3000 Wiring Harness

Understanding common issues and solutions related to the Curtis Sno Pro 3000 wiring harness can save time and prevent unnecessary downtime during snow removal operations. This section addresses some of the most frequently asked questions regarding troubleshooting, maintenance, and replacement of this critical component. Addressing these questions provides valuable insights for ensuring optimal performance and longevity of the plow’s electrical system. Knowing the answers to these questions empowers operators to diagnose and resolve common wiring issues efficiently.

How often should I inspect my Curtis Sno Pro 3000 wiring harness?

It is recommended to inspect the wiring harness at least twice a year, once before the start of the snow season and again at the end. Regular inspections can help identify and address any potential issues before they lead to major problems. Additionally, any time the plow experiences electrical issues or malfunctions, a thorough inspection of the wiring harness should be performed to rule out any wiring-related causes.

What are the common signs of a failing Curtis Sno Pro 3000 wiring harness?

Common signs of a failing wiring harness include intermittent plow operation, dim or flickering lights, and blown fuses. Also, visible signs of damage, such as frayed wires, corroded connectors, or melted insulation, can indicate a failing harness. If any of these symptoms are present, it’s important to inspect the wiring harness thoroughly and address any issues promptly to avoid further damage or downtime.

Can I repair a damaged Curtis Sno Pro 3000 wiring harness, or should I replace it?

Minor damage, such as a small cut or abrasion in the insulation, can often be repaired using electrical tape or liquid electrical tape. However, if the damage is more extensive, such as a broken wire or severely corroded connector, it is generally recommended to replace the entire wiring harness. Attempting to repair major damage can be unreliable and may lead to further electrical problems. Replacing the harness ensures a reliable and long-lasting solution.

What type of grease should I use to protect the connectors on my Curtis Sno Pro 3000 wiring harness?

Dielectric grease is the recommended type of grease for protecting the connectors on the wiring harness. This type of grease is non-conductive and helps prevent corrosion and moisture from entering the connectors. Applying a thin layer of dielectric grease to the connectors during installation and after each inspection can significantly extend the lifespan of the wiring harness.

How do I properly disconnect and reconnect the Curtis Sno Pro 3000 wiring harness?

Before disconnecting the wiring harness, ensure that the power to the snowplow is turned off. Carefully disconnect each connector, taking note of its location and orientation. When reconnecting the harness, ensure that each connector is securely fastened and that the locking mechanisms are engaged. Double-check all connections to ensure they are properly seated before turning the power back on.

Where can I find a replacement Curtis Sno Pro 3000 wiring harness?

Replacement wiring harnesses can be found at authorized Curtis snowplow dealers, online retailers specializing in snowplow parts, and some automotive parts stores. When purchasing a replacement harness, ensure that it is specifically designed for the Curtis Sno Pro 3000 model to ensure compatibility. Using the wrong wiring harness can lead to electrical issues and damage to the snowplow.

Proper installation of the Curtis Sno Pro 3000 wiring harness is essential for ensuring the safe and efficient operation of the snowplow. Before starting the installation process, it’s important to consult the manufacturer’s instructions and ensure that you have all the necessary tools and materials. Routing the wiring harness away from moving parts and sharp edges can help prevent damage and prolong its lifespan. Securing the harness with zip ties or clamps can also help prevent chafing and vibration.

Additionally, using the correct connectors and terminals is crucial for ensuring a reliable electrical connection. Avoid using mismatched or damaged connectors, as these can lead to intermittent electrical problems. When making connections, ensure that the wires are properly crimped and that the connections are tight and secure. Using heat shrink tubing to protect the connections from moisture and corrosion is also recommended. Following these steps can help ensure a successful and long-lasting installation.

Troubleshooting electrical issues related to the Curtis Sno Pro 3000 wiring harness may involve checking fuses, relays, and switches. A blown fuse can indicate a short circuit or overload in the wiring system. Relays can fail due to corrosion or wear, causing intermittent plow operation. Switches can also become damaged or corroded, leading to electrical problems. Using a multimeter to test the voltage and continuity of these components can help identify any faulty parts.

Key Aspects of the Curtis Sno Pro 3000 Wiring Harness

Understanding the key aspects of the Curtis Sno Pro 3000 wiring harness is crucial for maintaining and troubleshooting your snowplow. These aspects encompass the various components, functions, and considerations that contribute to the harness’s overall performance and reliability. Considering the part of speech is noun of “curtis sno pro 3000 wiring harness”, we can delve into various dimensions related to that, the harness is a crucial part of snowplow.

Compatibility

Ensuring the wiring harness is specifically designed for the Curtis Sno Pro 3000 model is paramount. Incompatible harnesses can lead to electrical issues, damage to the plow, and voided warranties. Always verify the part number and specifications before purchasing a replacement or performing any modifications.

Durability

The wiring harness is exposed to harsh weather conditions, including snow, ice, salt, and extreme temperatures. A durable harness is constructed from high-quality materials that can withstand these elements. Features such as weatherproof connectors, abrasion-resistant insulation, and corrosion-resistant terminals are essential for long-lasting performance.

Installation

Proper installation is critical for ensuring the reliable operation of the wiring harness. Following the manufacturer’s instructions and taking care to route the harness away from moving parts and sharp edges can help prevent damage and prolong its lifespan. Securely fastening the harness with zip ties or clamps can also help prevent chafing and vibration.

A comprehensive understanding of these key aspects enables users to proactively address potential issues, ensuring the continued functionality of the Curtis Sno Pro 3000 wiring harness and maximizing the lifespan of their snowplow. This includes regular inspections, proper maintenance, and timely replacements when necessary.

Overall, the Curtis Sno Pro 3000 wiring harness is a vital component of the snowplow system. Its proper functioning is essential for ensuring the safe and efficient removal of snow. By understanding the key aspects of the wiring harness and following proper maintenance practices, operators can minimize downtime and maximize the performance of their snowplow.

Essential Tips for Maintaining Your Curtis Sno Pro 3000 Wiring Harness

Proper maintenance is crucial for ensuring the longevity and reliability of your Curtis Sno Pro 3000 wiring harness. Regular inspections, preventative measures, and timely repairs can help prevent electrical issues and keep your snowplow operating at peak performance. Implementing these essential tips can save you time, money, and frustration in the long run. Taking proactive steps to maintain your wiring harness is a worthwhile investment.

These tips are designed to provide practical guidance on how to properly care for your Curtis Sno Pro 3000 wiring harness. By following these recommendations, you can minimize the risk of electrical problems, reduce downtime, and extend the lifespan of your wiring harness. These tips cover everything from basic inspection techniques to advanced troubleshooting methods. Keep in mind, regular upkeep can significantly improve snowplow’s performance.

Regularly Inspect the Wiring Harness

Inspect the wiring harness at least twice a year, once before the start of the snow season and again at the end. Look for any signs of physical damage, such as cuts, abrasions, or cracks in the insulation. Also, check the connectors for corrosion or loose connections. Addressing any issues promptly can prevent them from escalating into major problems.

Apply Dielectric Grease to Connectors

Apply a thin layer of dielectric grease to the connectors on the wiring harness during installation and after each inspection. Dielectric grease is non-conductive and helps prevent corrosion and moisture from entering the connectors. This simple step can significantly extend the lifespan of the wiring harness.

Secure the Wiring Harness

Ensure that the wiring harness is properly secured to the snowplow frame using zip ties or clamps. This will help prevent the harness from chafing against moving parts or sharp edges, which can lead to damage. Properly securing the harness can also reduce vibration, which can loosen connections and cause electrical problems.

Avoid Overloading the Electrical System

Avoid overloading the electrical system by adding excessive accessories or modifications. Overloading the system can cause the wiring harness to overheat and fail. If you need to add additional accessories, consult the manufacturer’s recommendations and ensure that the electrical system is properly sized to handle the additional load.

Use the Correct Fuses

Always use the correct fuses for the electrical system. Using the wrong fuses can lead to blown fuses or even damage to the wiring harness. Consult the manufacturer’s specifications to determine the correct fuse ratings for each circuit.

Keep the Wiring Harness Clean

Keep the wiring harness clean and free from dirt, debris, and chemicals. These contaminants can corrode the wires and connectors, leading to electrical problems. Periodically clean the wiring harness with a mild detergent and water, and rinse thoroughly. Be sure to dry the harness completely before reconnecting it.

Store the Snowplow Properly

When storing the snowplow for the off-season, protect the wiring harness from the elements. Store the plow in a dry, covered location to prevent moisture and corrosion from damaging the harness. Consider using a protective cover to shield the harness from sunlight and other environmental factors.

In conclusion, the Curtis Sno Pro 3000 wiring harness is a critical component of the snowplow system, responsible for ensuring the reliable and efficient operation of all electrical functions. A properly functioning wiring harness is essential for safe and effective snow removal. Regular maintenance, including inspections, cleaning, and the application of dielectric grease, can help extend the lifespan of the harness and prevent costly repairs. By following the tips outlined in this article, snowplow operators can ensure that their Curtis Sno Pro 3000 wiring harness remains in optimal condition.

Understanding the importance of the Curtis Sno Pro 3000 wiring harness is crucial for anyone operating a snowplow. Its role in powering and controlling the plow’s various functions cannot be overstated. Neglecting the maintenance and care of this vital component can lead to costly repairs, downtime, and even safety hazards. With proper attention and care, you can ensure that your plow is always ready to tackle whatever winter throws your way.

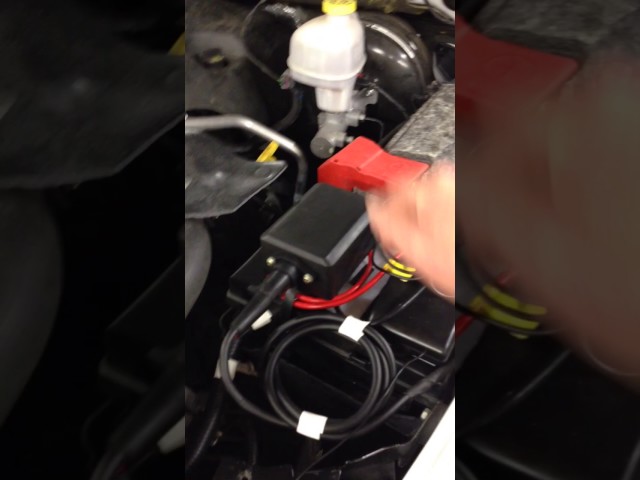

Youtube Video: