Cat 5 wiring configuration refers to the arrangement of wires within a Category 5 cable, a type of network cabling used in Ethernet networks. It specifies the order in which the eight individual wires are connected to the RJ-45 connectors at each end of the cable. The two most common configurations are T568A and T568B. These configurations ensure that the wires are properly aligned and connected to the correct pins on the connectors, allowing for optimal signal transmission.

Cat 5 wiring configuration is crucial for maintaining the integrity and performance of Ethernet networks. Proper configuration minimizes signal interference, reduces errors, and ensures reliable data transmission. It is essential for supporting high-speed data transfer and ensuring the stability of network connections. Historically, Cat 5 cables have been widely used in home and office networks, but with the advent of faster technologies such as Cat 6 and Cat 7, they are gradually being replaced.

Understanding Cat 5 wiring configuration is important for network installers, IT professionals, and anyone involved in setting up or maintaining Ethernet networks. Proper configuration is essential for ensuring optimal network performance and avoiding connectivity issues. The following sections will delve deeper into the specifics of Cat 5 wiring configuration, including the pinouts, the T568A and T568B standards, and best practices for installation and testing.

Cat 5 Wiring Configuration

Cat 5 wiring configuration is crucial for maintaining the integrity and performance of Ethernet networks. Proper configuration ensures reliable data transmission and minimizes signal interference and errors. Here are seven key aspects to consider:

- Pinouts: The arrangement of wires within the RJ-45 connectors.

- Standards: T568A and T568B are the two common wiring standards.

- Color codes: Each wire is assigned a specific color code for easy identification.

- Termination: The process of connecting the wires to the RJ-45 connectors.

- Testing: Verifying the continuity and performance of the cable using a cable tester.

- Installation: Proper installation methods ensure optimal signal quality.

- Maintenance: Regular inspection and maintenance prevent issues and ensure longevity.

These aspects are interconnected and essential for a well-functioning Cat 5 network. For instance, using the correct pinouts and following the T568A or T568B standard ensures proper alignment and connectivity of wires. Proper termination and testing guarantee reliable data transmission. Regular maintenance, such as checking for loose connections and cable damage, helps maintain network stability. Understanding these aspects enables network installers and IT professionals to effectively configure, install, and maintain Cat 5 wiring systems.

Pinouts

In Cat 5 wiring configuration, pinouts refer to the specific order in which the eight individual wires are connected to the eight pins on an RJ-45 connector. This arrangement is crucial for ensuring proper signal transmission and maintaining the integrity of the network connection.

The two most common pinout configurations are T568A and T568B. These standards define the color-coding and the order of the wires within the RJ-45 connector. Adhering to these standards ensures compatibility between devices and network components.

For instance, in the T568A configuration, the orange/white wire is connected to pin 1, the orange wire to pin 2, the green/white wire to pin 3, and so on. This arrangement allows for a consistent and reliable connection between devices, regardless of the cable length or the type of equipment used.

Proper pinouts are essential for maintaining signal quality and minimizing interference. Incorrect pinouts can lead to data transmission errors, network instability, and connectivity issues. Therefore, it is crucial for network installers and IT professionals to have a clear understanding of pinouts and to follow the established standards when configuring Cat 5 cables.

Overall, pinouts are a fundamental aspect of Cat 5 wiring configuration, ensuring proper signal transmission, maintaining network integrity, and facilitating compatibility between devices. Understanding and adhering to pinout standards is essential for the successful installation and maintenance of Cat 5 networks.

Standards

In Cat 5 wiring configuration, standards play a critical role in ensuring compatibility, reliability, and optimal performance of network connections. The two most prevalent standards are T568A and T568B, which define the specific arrangement of wires within the RJ-45 connectors.

These standards establish a uniform color-coding scheme and pinout configuration for Cat 5 cables. Adhering to these standards ensures that devices and network components can communicate effectively, regardless of the cable length or the equipment used. For instance, in both T568A and T568B configurations, the orange/white wire is connected to pin 1, and the orange wire is connected to pin 2. This consistency allows for seamless data transmission and minimizes the risk of errors.

The importance of these standards extends beyond compatibility. They also impact signal quality and network performance. Proper wiring according to T568A or T568B standards reduces signal interference, minimizes crosstalk, and maintains the integrity of the data transmission. This is particularly crucial in high-speed network environments, where even minor deviations from the standards can lead to data corruption or network instability.

Understanding and adhering to T568A and T568B standards is essential for network installers, IT professionals, and anyone involved in the installation and maintenance of Cat 5 networks. By following these standards, they can ensure reliable data transmission, maintain network stability, and avoid compatibility issues. Moreover, these standards serve as a foundation for troubleshooting and resolving network connectivity problems, enabling efficient and effective network management.

Color codes

In Cat 5 wiring configuration, color codes play a crucial role in facilitating easy identification and ensuring proper wiring. Each of the eight individual wires within a Cat 5 cable is assigned a unique color code, making it easier to distinguish them and connect them correctly to the RJ-45 connectors.

The color-coding scheme is standardized to maintain consistency across different cables and installations. For instance, in both T568A and T568B configurations, the orange/white wire is always connected to pin 1, and the orange wire is connected to pin 2. This color-coding simplifies the wiring process, minimizing errors and ensuring reliable connections.

The practical significance of color codes in Cat 5 wiring configuration extends beyond ease of identification. Color-coded wires enable faster and more accurate troubleshooting. By tracing the colored wires, network installers and IT professionals can quickly identify breaks, misconnections, or other faults within the cabling system. This expedites the troubleshooting process, minimizing downtime and ensuring efficient network maintenance.

Furthermore, color codes are essential for adhering to industry standards and best practices. Standardized color-coding ensures compatibility between different network devices and components, regardless of the manufacturer or the specific application. This standardization facilitates interoperability and reduces the risk of errors during installation and maintenance.

In summary, color codes are an integral part of Cat 5 wiring configuration, providing several key benefits. They simplify identification and wiring, expedite troubleshooting, and ensure compliance with industry standards. Understanding and utilizing color codes correctly is essential for network installers, IT professionals, and anyone involved in the installation and maintenance of Cat 5 networks.

Termination

Termination is an essential aspect of Cat 5 wiring configuration, directly impacting the reliability, performance, and longevity of the network connection.

- Proper Termination Techniques: Proper termination involves carefully connecting the individual wires within the Cat 5 cable to the corresponding pins on the RJ-45 connector. This process requires precision and adherence to industry standards to ensure optimal signal transmission.

- Impact on Signal Quality: Precise termination minimizes signal loss and interference, resulting in a strong and stable network connection. Poor termination techniques, such as loose connections or incorrect wire pairing, can lead to signal degradation, data errors, and network instability.

- Compliance with Standards: Termination practices must comply with established industry standards, such as TIA/EIA-568-B, to ensure compatibility with network devices and infrastructure. Adhering to these standards guarantees reliable connectivity and interoperability.

- Durability and Longevity: Properly terminated connections are more durable and less prone to damage or failure over time. Securely connecting the wires to the RJ-45 connector prevents loose connections, corrosion, and other issues that can affect the performance and longevity of the network.

Overall, proper termination is crucial for maximizing the benefits of Cat 5 wiring configuration. By ensuring precise and standards-compliant termination, network installers can create reliable, high-performing, and long-lasting network connections.

Testing

Testing is an essential aspect of Cat 5 wiring configuration, ensuring that the installed cabling meets industry standards, performs optimally, and provides reliable network connectivity.

-

Continuity Testing:

Continuity testing verifies that each individual wire within the Cat 5 cable is intact and properly connected from one end to the other. This test ensures that there are no breaks or faults in the cabling, which could lead to signal loss or data errors.

-

Performance Testing:

Performance testing evaluates the overall performance of the Cat 5 cable, including parameters such as signal attenuation, delay skew, and noise resistance. These tests ensure that the cable meets the required specifications for data transmission speed and signal quality.

-

Cable Testers:

Cable testers are specialized tools used to perform continuity and performance testing on Cat 5 cables. These testers generate test signals and analyze the resulting signals to identify any faults or performance issues.

-

Industry Standards:

Testing procedures and acceptance criteria for Cat 5 cables are defined by industry standards, such as TIA/EIA-568-B. Adhering to these standards ensures that the cabling meets the required specifications for reliable network performance.

By conducting thorough testing during Cat 5 wiring configuration, network installers and IT professionals can proactively identify and resolve any issues with the cabling, ensuring that the network operates at its optimal performance and meets the intended application requirements.

Installation

In the context of Cat 5 wiring configuration, proper installation methods play a critical role in ensuring optimal signal quality and maintaining the integrity of the network connection.

-

Cable Routing and Management:

Proper cable routing and management practices minimize signal interference and maintain the physical integrity of the cables. This involves avoiding sharp bends, excessive tension, and exposure to environmental hazards that could damage the cables or affect their performance.

-

Connector Selection and Termination:

Choosing high-quality connectors and terminating them correctly is essential for maintaining signal strength and preventing data errors. Proper termination techniques ensure secure connections between the cables and the connectors, minimizing signal loss and ensuring reliable data transmission.

-

Cable Length and Signal Attenuation:

Signal attenuation, the loss of signal strength over distance, is a factor to consider during installation. Using cables within the recommended length limits and avoiding excessive cable runs helps maintain strong signal quality and minimizes the risk of data corruption.

-

Environmental Conditions:

Environmental conditions, such as temperature, humidity, and exposure to chemicals, can impact the performance and longevity of Cat 5 cables. Proper installation methods include protecting cables from extreme temperatures, moisture, and potential sources of damage to ensure reliable operation in various environments.

By adhering to proper installation methods, network installers and IT professionals can optimize signal quality, minimize interference, and enhance the overall performance and reliability of Cat 5 wiring configurations.

Maintenance

Regular maintenance is an integral component of Cat 5 wiring configuration, playing a crucial role in maintaining optimal network performance, preventing issues, and ensuring the longevity of the cabling system.

By conducting routine inspections and performing necessary maintenance tasks, network administrators can proactively identify and address potential problems before they escalate into major failures. These tasks include checking for loose connections, cable damage, corrosion, and environmental hazards that could affect the integrity of the cabling. Regular cleaning and dusting of cables and connectors can also help prevent the accumulation of dirt and debris, which can degrade signal quality over time.

Proper maintenance practices contribute to the longevity of Cat 5 wiring by minimizing wear and tear, reducing the risk of cable failures, and extending the overall lifespan of the network infrastructure. This, in turn, reduces the need for costly repairs and replacements, minimizing downtime and maximizing the return on investment in the cabling system.

In real-life scenarios, regular maintenance has proven to be highly effective in preventing network issues and ensuring the smooth operation of Cat 5 cabling systems. For instance, in a corporate office setting, implementing a regular maintenance schedule involving periodic cable inspections and cleaning resulted in a significant reduction in network downtime and improved overall network stability.

Understanding the importance of maintenance as a component of Cat 5 wiring configuration is essential for network administrators and IT professionals. By incorporating regular maintenance into their network management strategies, they can proactively address potential issues, minimize disruptions, and ensure the longevity and reliability of their network infrastructure.

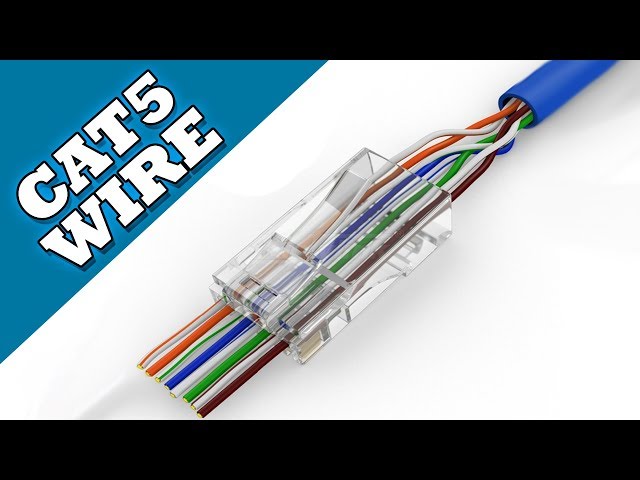

Visualizing Cat 5 Wiring Configuration

Cat 5 wiring configuration involves arranging the eight individual wires within a Cat 5 cable according to specific standards to ensure optimal signal transmission and network performance. Visual aids, such as charts and diagrams, can greatly enhance the understanding and execution of Cat 5 wiring configurations.

Chart Examples:

- Pinout Chart: A table that illustrates the arrangement of wires within an RJ-45 connector, showing the corresponding pin numbers and color codes for both T568A and T568B standards.

- Wiring Diagram: A schematic representation of a Cat 5 cable, depicting the color-coded wires and their connections to the RJ-45 connectors at each end.

Steps to Create a Cat 5 Wiring Configuration Chart or Diagram:

- Identify the Standard: Determine whether to use the T568A or T568B wiring standard.

- Label the Pins: Mark the eight pins on the RJ-45 connector with their corresponding numbers.

- Color-Code the Wires: Assign the appropriate color codes to each wire based on the chosen standard.

- Connect the Wires: Physically connect the wires to the pins according to the pinout chart.

- Verify the Connections: Use a cable tester to ensure that all wires are properly connected and there are no shorts or breaks.

Conclusion:

Charts and diagrams are valuable tools for visualizing and understanding Cat 5 wiring configurations. By utilizing these visual aids, network installers and IT professionals can ensure accurate and efficient wiring, leading to optimal network performance and minimizing troubleshooting efforts.

Frequently Asked Questions (FAQs) on Cat 5 Wiring Configuration

This section addresses commonly asked questions and misconceptions surrounding Cat 5 wiring configuration, providing clear and concise answers to guide network installers and IT professionals.

Question 1: What is the difference between T568A and T568B wiring standards?

Answer: T568A and T568B are two commonly used wiring standards for Cat 5 cables. While they both follow the same pinout configuration, the color arrangement of the wires differs. T568A is primarily used in North America, while T568B is more common in Europe and other regions.

Question 2: Which wiring standard should I use for my Cat 5 network?

Answer: The choice between T568A and T568B depends on the region and the compatibility requirements of the network devices being used. If unsure, it is recommended to use T568A for consistency with North American standards.

Question 3: Can I use Cat 5 cables for Gigabit Ethernet?

Answer: Yes, Cat 5 cables can support Gigabit Ethernet speeds (1000 Mbps) under certain conditions. However, for optimal performance and reliability, it is recommended to use Cat 5e or Cat 6 cables, which are specifically designed for Gigabit Ethernet and higher.

Question 4: What are the common causes of Cat 5 wiring issues?

Answer: Common causes of Cat 5 wiring issues include improper termination, loose connections, cable damage, and environmental factors such as moisture or extreme temperatures. Regular inspection and maintenance can help prevent and identify these issues.

Question 5: How do I troubleshoot Cat 5 wiring problems?

Answer: Troubleshooting Cat 5 wiring problems involves using a cable tester to verify continuity, identify breaks or shorts, and check for proper termination. Visual inspection of the cables and connectors can also help identify potential issues.

Question 6: What are best practices for Cat 5 wiring installation?

Answer: Best practices for Cat 5 wiring installation include using high-quality cables and connectors, following the correct wiring standard, avoiding sharp bends or excessive tension, and protecting the cables from potential damage or interference.

Summary: Understanding Cat 5 wiring configuration is essential for ensuring a reliable and high-performing network. This FAQ section has provided answers to common questions, addressing concerns and providing guidance for successful Cat 5 wiring installations.

Transition to the next article section: For further insights into Cat 5 wiring, the following section explores advanced topics such as cable testing and troubleshooting methodologies.

Conclusion

In the realm of network infrastructure, Cat 5 wiring configuration plays a pivotal role in ensuring reliable and efficient data transmission. This article has explored the intricacies of Cat 5 wiring, including pinouts, standards, color-coding, termination, testing, installation, and maintenance. Each aspect contributes to the overall performance and longevity of a Cat 5 network.

Understanding Cat 5 wiring configuration empowers network professionals to design, install, and troubleshoot network cabling systems effectively. By adhering to industry standards and best practices, they can create robust and high-performing networks that meet the demands of modern applications and devices.

Youtube Video: