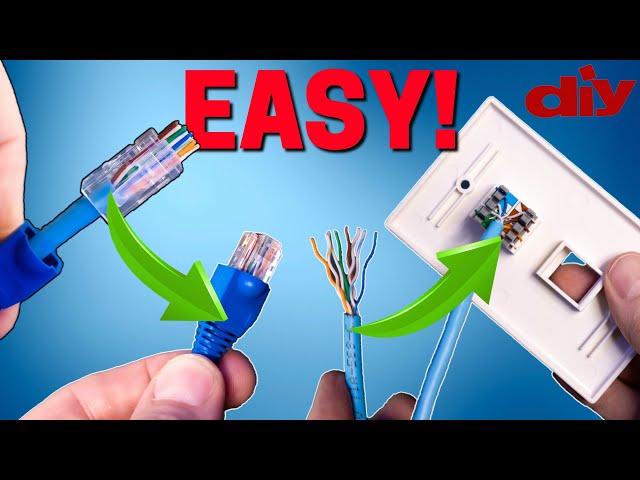

Wiring a Cat 5 wall jack involves connecting individual wires to the corresponding terminals on the jack to establish a network connection. This process requires attention to detail and precision to ensure a secure and functional connection.

Cat 5 wall jacks are crucial components of wired network infrastructure, enabling the transmission of data, voice, and video signals over Ethernet cables. They provide a standardized interface for connecting devices to a network and facilitate reliable data transfer. Moreover, Cat 5 jacks support higher bandwidth and speeds compared to older Cat 3 jacks, making them suitable for modern network applications.

In this article, we will delve into the steps involved in wiring a Cat 5 wall jack, highlighting the importance of proper wire preparation, accurate termination techniques, and testing procedures to ensure optimal performance. We will also explore the benefits of using Cat 5 wall jacks in various networking scenarios and provide additional resources for further exploration.

Wiring Cat 5 Wall Jack

Proper wiring of Cat 5 wall jacks is crucial for establishing a stable and reliable network connection. Here are six key aspects to consider:

- Preparation: Gather necessary tools and materials, and prepare the wires by stripping and straightening them.

- Termination: Connect the wires to the correct terminals on the jack using a punchdown tool.

- Testing: Verify the wiring using a cable tester to ensure proper connectivity.

- Standards: Adhere to industry standards, such as TIA/EIA-568-B, for reliable performance.

- Safety: Observe safety precautions while working with electrical components.

- Tools: Utilize appropriate tools, such as a punchdown tool and cable stripper, for efficient and accurate wiring.

Understanding these aspects and following best practices are essential for successful Cat 5 wall jack wiring. Proper preparation ensures smooth wire insertion, while accurate termination creates secure connections. Testing guarantees reliable data transmission, and adhering to standards ensures compatibility and performance. Safety considerations protect against electrical hazards, and using the right tools simplifies the process. By considering these key aspects, you can ensure a robust and functional network connection.

Preparation

In the context of “wiring Cat 5 wall jack,” preparation is of paramount importance. It involves gathering the necessary tools, such as a punchdown tool, cable stripper, and cable tester, as well as high-quality materials, including Cat 5 cables and wall jacks. Proper preparation also includes preparing the wires by stripping and straightening them.

- Stripping the wires: The outer jacket of the Cat 5 cable needs to be carefully stripped back using a cable stripper to expose the individual twisted pairs of wires. This must be done precisely to avoid damaging the delicate copper conductors inside.

- Straightening the wires: Once the wires are stripped, they need to be straightened and untwisted. This ensures that they can be easily inserted into the correct terminals on the wall jack during termination.

Adequate preparation, including proper wire stripping and straightening, lays the foundation for a successful and reliable Cat 5 wall jack wiring. It helps ensure that the wires are properly terminated, making a secure and efficient connection for data transmission.

Termination

Termination is a crucial step in wiring a Cat 5 wall jack, ensuring a secure and reliable connection. It involves connecting the individual wires of the Cat 5 cable to the corresponding terminals on the wall jack using a punchdown tool.

-

Precision and Accuracy

Precision and accuracy are paramount during termination. Each wire must be carefully inserted into the correct terminal and terminated properly using the punchdown tool. This ensures a solid connection that can withstand physical movement and vibrations without compromising signal integrity. -

Color Coding and Standards

Cat 5 cables follow a specific color-coding scheme, and it is essential to adhere to these standards during termination. The TIA/EIA-568-B standard defines the color-coding for each wire pair, ensuring compatibility with other network devices and preventing misconfigurations. -

Punchdown Tool

A punchdown tool is specifically designed for terminating wires on wall jacks. It features a blade that cuts and inserts the wire into the terminal in one motion. Using the appropriate punchdown tool helps ensure proper termination and prevents damage to the wires or terminals. -

Testing and Verification

After termination, it is essential to test the wiring using a cable tester. This verifies that each wire is correctly connected and that the signal transmission is within acceptable parameters. Testing ensures that the wall jack is functioning as intended and ready for use in a network.

Proper termination is vital for the performance and reliability of a Cat 5 wall jack. By following these guidelines and utilizing the correct tools and techniques, you can ensure a secure and efficient connection that meets industry standards and supports high-speed data transmission.

Testing

Testing is a critical step in wiring a Cat 5 wall jack as it ensures that the wiring is correct and the jack is functioning properly. A cable tester is used to send a signal through the wires and verify that each wire is connected to the correct terminal on the jack and that the signal is being transmitted clearly.

-

Electrical Continuity

The cable tester verifies the electrical continuity of each wire, ensuring that there are no breaks or shorts in the wiring. This is important because any break or short can disrupt the signal transmission and cause network connectivity issues.

-

Wire Mapping

The cable tester can also be used to verify the wire mapping, which is the order in which the wires are connected to the terminals on the jack. This is important because the wire mapping must match the standard wiring scheme (such as TIA/EIA-568-B) for the network to function properly.

-

Signal Strength

The cable tester can also measure the signal strength being transmitted through the wires. This is important because a weak signal can indicate a problem with the wiring or the jack, which could lead to slow network speeds or intermittent connectivity.

-

Troubleshooting

If the cable tester detects a problem with the wiring, it can help to identify the location of the problem. This can be useful for troubleshooting and repairing network connectivity issues.

By using a cable tester to verify the wiring of a Cat 5 wall jack, you can ensure that the jack is installed correctly and is functioning properly. This will help to prevent network connectivity issues and ensure a reliable and efficient network connection.

Standards

In the context of wiring Cat 5 wall jacks, adhering to industry standards, such as TIA/EIA-568-B, is crucial for ensuring reliable performance and compatibility within a network infrastructure.

-

Ensuring Compatibility

Industry standards, like TIA/EIA-568-B, establish guidelines for the wiring of Cat 5 wall jacks, including the color-coding of wires and the termination sequence. By following these standards, network installers can ensure that all wall jacks are wired consistently, allowing for seamless data transmission and compatibility with other network devices.

-

Optimizing Performance

Adhering to industry standards helps optimize the performance of Cat 5 wall jacks by ensuring that they meet specific electrical and transmission requirements. The TIA/EIA-568-B standard defines parameters for wire gauge, insulation, and termination techniques, which are crucial for maintaining signal integrity and minimizing data loss or errors.

-

Facilitating Troubleshooting

Standardized wiring practices make it easier to troubleshoot network issues. By following industry standards, network technicians can quickly identify and resolve problems related to wall jack wiring, reducing downtime and ensuring the efficient operation of the network.

-

Maintaining Safety

Industry standards also incorporate safety considerations into the wiring of Cat 5 wall jacks. Proper termination techniques, as outlined in TIA/EIA-568-B, help prevent electrical hazards, such as short circuits or loose connections, which could pose a safety risk in commercial or residential environments.

In conclusion, adhering to industry standards when wiring Cat 5 wall jacks is paramount for achieving reliable performance, ensuring compatibility, and maintaining safety within a network infrastructure. By following established guidelines, network installers can create a robust and efficient network foundation that supports seamless data transmission and minimizes potential issues.

Safety

When wiring Cat 5 wall jacks, safety should be a top priority. Electrical components, such as wall jacks and cables, carry electrical current, posing potential hazards if not handled properly.

-

Electrical Hazards

Electrical hazards are associated with working with electrical components. These hazards include electric shock, burns, and even electrocution. It is crucial to take precautions to avoid these hazards, such as wearing insulated gloves and using proper tools.

-

Fire Hazards

Electrical components can also pose fire hazards. For example, loose connections or faulty wiring can generate heat, which could ignite nearby materials. It is important to ensure that all electrical connections are tight and secure, and to avoid overloading circuits.

-

Personal Protective Equipment

When working with electrical components, it is essential to wear appropriate personal protective equipment (PPE). This includes insulated gloves, safety glasses, and non-conductive shoes. PPE can help protect you from electrical shock and other hazards.

-

Work Environment

The work environment should also be taken into consideration when working with electrical components. The area should be well-lit and ventilated, and free of any potential hazards such as water or flammable materials.

-

Training and Qualifications

It is important to have proper training and qualifications before working with electrical components. This will ensure that you have the knowledge and skills to work safely and effectively.

By observing safety precautions while working with electrical components, you can help prevent accidents and injuries. Always prioritize safety, and take the necessary steps to protect yourself and others.

Tools

Wiring Cat 5 wall jacks requires the use of appropriate tools to ensure efficient and accurate installation. These tools include a punchdown tool and a cable stripper, each serving a specific function in the process.

-

Punchdown Tool

A punchdown tool is a specialized tool designed to terminate wires on wall jacks. It features a blade that cuts and inserts the wire into the terminal in one motion. Using a punchdown tool ensures secure and reliable connections, reducing the risk of loose wires or intermittent connections.

-

Cable Stripper

A cable stripper is used to remove the outer jacket of the Cat 5 cable, exposing the individual twisted pairs of wires. Precision stripping is crucial to avoid damaging the delicate copper conductors inside the cable. Proper stripping also facilitates accurate termination and prevents short circuits or other wiring issues.

The use of appropriate tools, such as a punchdown tool and cable stripper, is essential for successful Cat 5 wall jack wiring. These tools enable installers to prepare, terminate, and test the wiring efficiently and accurately, ensuring a reliable and high-performance network connection.

Essential Guidelines for Wiring Cat 5 Wall Jacks

Wiring Cat 5 wall jacks is a crucial step in establishing a reliable and efficient network infrastructure. To ensure proper installation and optimal performance, it is essential to follow specific guidelines and utilize appropriate tools. This guide provides a comprehensive overview of the steps involved in wiring Cat 5 wall jacks, including essential tools, safety precautions, and industry standards.

The following chart outlines the key steps involved in wiring Cat 5 wall jacks:

| Step | Description |

|---|---|

| 1 | Gather necessary tools and materials, including a punchdown tool, cable stripper, cable tester, Cat 5 cable, and wall jack. |

| 2 | Prepare the wires by stripping the outer jacket of the Cat 5 cable and straightening the individual twisted pairs of wires. |

| 3 | Terminate the wires to the correct terminals on the wall jack using a punchdown tool. |

| 4 | Test the wiring using a cable tester to verify proper connectivity. |

| 5 | Adhere to industry standards, such as TIA/EIA-568-B, to ensure compatibility and reliable performance. |

| 6 | Observe safety precautions while working with electrical components, including wearing appropriate personal protective equipment and working in a safe environment. |

By following these guidelines and utilizing the appropriate tools, you can ensure that your Cat 5 wall jacks are wired correctly, providing a solid foundation for a robust and efficient network infrastructure.

Frequently Asked Questions about Wiring Cat 5 Wall Jacks

Wiring Cat 5 wall jacks is a common task for network installers and IT professionals. Here are some frequently asked questions and answers to help you understand the process better:

Question 1: What tools do I need to wire a Cat 5 wall jack?

You will need a punchdown tool, cable stripper, cable tester, Cat 5 cable, and wall jack.

Question 2: How do I prepare the wires for termination?

Strip the outer jacket of the Cat 5 cable to expose the individual twisted pairs of wires. Then, straighten the wires and cut them to the appropriate length.

Question 3: How do I terminate the wires to the wall jack?

Use a punchdown tool to insert the wires into the correct terminals on the wall jack. Make sure to follow the color-coding standard (TIA/EIA-568-B) to ensure proper connectivity.

Question 4: How do I test the wiring?

Use a cable tester to verify that each wire is properly connected and that the signal is being transmitted clearly.

Question 5: What safety precautions should I take when wiring Cat 5 wall jacks?

Always wear appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses. Work in a well-lit and ventilated area, and avoid contact with any live electrical components.

Question 6: Why is it important to follow industry standards when wiring Cat 5 wall jacks?

Following industry standards, such as TIA/EIA-568-B, ensures compatibility with other network devices and optimizes performance. It also facilitates troubleshooting and maintenance.

By understanding these FAQs, you can gain a better understanding of the process of wiring Cat 5 wall jacks and ensure a successful installation.

Transition to the next article section

Conclusion

Wiring Cat 5 wall jacks is a fundamental skill for network installers and IT professionals. By following the guidelines outlined in this article, you can ensure that your wall jacks are wired correctly, providing a solid foundation for a robust and efficient network infrastructure.

Remember to use the appropriate tools, adhere to industry standards, and prioritize safety throughout the process. By doing so, you can minimize potential issues, ensure reliable connectivity, and support the smooth operation of your network.

Youtube Video: