Understanding honeywell zone valve wiring is crucial for maintaining efficient and effective home heating and cooling systems. Zone valves, especially those manufactured by Honeywell, play a vital role in directing the flow of water or steam to specific areas of a building, allowing for customized temperature control. Correct wiring ensures that these valves operate as intended, opening and closing in response to thermostat signals. Improperly wired zone valves can lead to uneven heating, system inefficiencies, and potential equipment damage. Therefore, a clear understanding of the wiring process is essential for homeowners and HVAC professionals alike.

The purpose of honeywell zone valve wiring is to accurately control the distribution of heated or cooled water to different zones within a building. These valves act as gatekeepers, opening or closing in response to signals from thermostats in each zone. The correct wiring configuration enables seamless communication between the thermostats and the zone valves, ensuring that each zone receives the appropriate amount of heating or cooling. This precision allows for energy savings and a more comfortable living environment, as unoccupied areas can be heated or cooled less frequently.

Proper honeywell zone valve wiring is more than just connecting wires; it’s about ensuring the entire zone heating system functions harmoniously. When wired correctly, each zone valve responds accurately to the thermostat, opening to allow flow when heat is called for and closing to prevent flow when the set temperature is reached. This responsiveness maximizes the efficiency of the heating system, preventing unnecessary energy waste. Furthermore, the right wiring configuration protects the zone valves themselves from damage, extending their lifespan and reducing the need for costly repairs.

Common Misconceptions About Honeywell Zone Valve Wiring

The topic of honeywell zone valve wiring frequently arises in various forums, social media, and even everyday conversations, indicating how relevant this issue is within society. One of the most common misconceptions surrounding this process is that all zone valves are wired the same way. While many Honeywell zone valves share similar wiring configurations, variations can exist depending on the specific model and system setup. Failing to consult the manufacturer’s instructions or wiring diagrams can lead to incorrect connections and system malfunctions.

Another misconception is that wiring a zone valve is a simple task that anyone can handle without proper knowledge. While the wiring itself might seem straightforward, understanding the electrical components, safety precautions, and potential consequences of incorrect wiring is essential. Attempting the wiring without proper expertise can result in electrical shocks, damage to the system components, and even fire hazards. Therefore, it’s always recommended to seek professional assistance if you’re unsure about any aspect of the wiring process. Ignoring the importance of correct voltage and polarity when performing honeywell zone valve wiring is a dangerous oversight.

Finally, some individuals believe that the color of the wires used in honeywell zone valve wiring is standardized and can be relied upon for accurate connections. While some conventions exist regarding wire colors, they are not universally followed, and relying solely on color coding can lead to errors. Always verify the specific function of each wire using a multimeter or wiring diagram to ensure correct connections. In addition, never assume the voltage needed and make sure to turn off the power when performing electrical connection.

Essential Tools and Materials for Honeywell Zone Valve Wiring

Successfully completing honeywell zone valve wiring requires having the right tools and materials on hand. These include a multimeter for testing voltage and continuity, wire strippers for preparing wires for connection, and wire connectors for making secure and reliable connections. In addition, a wiring diagram specific to your Honeywell zone valve model is essential for ensuring correct connections. Safety glasses and insulated gloves are also crucial for protecting yourself from electrical hazards.

Step-by-Step Guidelines for Honeywell Zone Valve Wiring

When performing honeywell zone valve wiring, always prioritize safety and accuracy. The following steps provide a general guideline, but it’s essential to consult the specific wiring diagram for your Honeywell zone valve model.

Step 1: Gather Your Tools and Materials

Before starting, ensure you have all the necessary tools and materials, including a multimeter, wire strippers, wire connectors, a wiring diagram, safety glasses, and insulated gloves. Verify that the replacement valve is identical to the old valve and rated at the same voltage.

Step 2: Turn Off the Power

Locate the circuit breaker that controls the power to the heating system and turn it off. This is a crucial safety precaution to prevent electrical shocks. Always double-check that the power is off using a multimeter before proceeding. You also can put a note at the breaker box so someone else doesn’t turn the breaker back on while you are working on it.

Step 3: Identify the Wires

Carefully examine the wiring diagram and identify the function of each wire connected to the zone valve. Common wires include those for power, thermostat signal, and end switch. Using a multimeter, confirm the voltage of each wire before disconnecting anything. Never touch the wires when the breaker is on, always turn off the power first.

Step 4: Disconnect the Old Valve

Using wire strippers, carefully disconnect the wires from the old zone valve. Take photographs or make detailed notes of the wire connections to ensure you can replicate them on the new valve. Do not cut all the wires at once, disconnect them one at a time so you don’t lose track of which wire is going where.

Step 5: Connect the New Valve

Referring to your notes or photographs and the wiring diagram, connect the wires to the corresponding terminals on the new zone valve. Use wire connectors to ensure secure and reliable connections. Be sure to follow the instructions from the product manual, because depending on the model, it might be slightly different than the model it is replacing.

Step 6: Test the Connections

Once all the wires are connected, turn the power back on at the circuit breaker. Use a multimeter to test the voltage at the zone valve terminals to ensure everything is working correctly. Have a second person turn up the thermostat and confirm the new zone valve opens and closes as it is designed to do.

Frequently Asked Questions About Honeywell Zone Valve Wiring

Many questions arise regarding honeywell zone valve wiring, reflecting the complexities and importance of this process. Understanding these common queries can help homeowners and HVAC professionals troubleshoot issues and ensure proper system operation.

What happens if I wire a Honeywell zone valve incorrectly?

Incorrect wiring of a Honeywell zone valve can lead to a variety of problems, ranging from minor inconveniences to significant system damage. If wired improperly, the valve may not open or close correctly, resulting in either no heat or continuous heat in a particular zone. This can lead to discomfort, energy waste, and potentially higher utility bills. Additionally, incorrect wiring can damage the valve itself, requiring costly repairs or replacements. In some cases, it can even cause electrical shorts or fire hazards, making it crucial to ensure the wiring is done correctly and safely.

How do I know which wires go where on a Honeywell zone valve?

The most reliable way to determine the correct wire connections on a Honeywell zone valve is to consult the wiring diagram specific to your model. These diagrams typically provide a clear visual representation of the wiring configuration, indicating which wires connect to which terminals. If the wiring diagram is not available, you can often find it online on the Honeywell website or through other HVAC resources. Additionally, using a multimeter to test the voltage and continuity of the wires can help identify their function and ensure they are connected to the correct terminals. Always turn off the power before testing to avoid electrical shock.

Can I replace a Honeywell zone valve myself, or do I need a professional?

Whether you can replace a Honeywell zone valve yourself depends on your level of electrical and HVAC knowledge and experience. If you are comfortable working with electrical wiring and have a good understanding of HVAC systems, you may be able to perform the replacement yourself. However, if you are unsure about any aspect of the process, it’s always best to seek professional assistance. A qualified HVAC technician can ensure the replacement is done safely and correctly, preventing potential damage to the system and ensuring optimal performance.

What is the purpose of the end switch on a Honeywell zone valve?

The end switch on a Honeywell zone valve serves to signal the boiler or circulator pump to turn on or off when a zone calls for heat. When the thermostat in a zone calls for heat, the zone valve opens, and the end switch closes, completing the circuit that activates the boiler or pump. Conversely, when the thermostat reaches the set temperature and the zone valve closes, the end switch opens, shutting off the boiler or pump. This ensures that the boiler or pump only operates when heat is actually needed, saving energy and reducing wear and tear on the equipment.

What should I do if my Honeywell zone valve is not opening or closing?

If your Honeywell zone valve is not opening or closing, there are several potential causes to investigate. First, check the thermostat to ensure it is properly set and functioning correctly. Then, verify that the zone valve is receiving power and that the wiring connections are secure. You can use a multimeter to test the voltage at the zone valve terminals. If the valve is receiving power but still not opening or closing, the valve motor may be faulty and need replacement. If you are unsure about how to troubleshoot the problem, it’s best to consult a qualified HVAC technician.

Are there different types of Honeywell zone valves, and do they all wire the same way?

Yes, Honeywell offers various types of zone valves, each designed for specific applications and system configurations. While many Honeywell zone valves share similar wiring configurations, variations can exist depending on the model and system setup. Some valves may have additional features or terminals, requiring different wiring connections. Therefore, it’s essential to consult the specific wiring diagram for your Honeywell zone valve model to ensure correct connections.

What is the recommended voltage for honeywell zone valve wiring?

The voltage depends on the particular model of Honeywell zone valve. In general, zone valves can operate at 24V, 120V, or 240V. It’s critical to confirm the correct voltage before wiring the valve. Using the wrong voltage can destroy the motor on the valve and possibly cause other problems with the HVAC system. Check the device manual or the sticker on the device itself to confirm the correct voltage needed before connecting the zone valve.

What is the function of each wire on a honeywell zone valve wiring system?

The function of each wire varies depending on the system. However, the most common wires are the line voltage wire, the neutral wire, and the thermostat wire. The line voltage wire provides the power to the zone valve, the neutral wire is the return path for the electrical current, and the thermostat wire is the signal from the thermostat telling the valve to open or close. Always consult the wiring diagram for your model of zone valve.

Correct honeywell zone valve wiring is about more than simply linking wires; it’s about ensuring an entire zoned heating system functions in perfect synchronicity. When wired correctly, each zone valve responds exactly to the thermostat, opening to allow flow when heat is demanded and closing to prevent flow when the set temperature is met. This responsiveness then maximizes the efficiency of your heating system.

Beyond efficiency, honeywell zone valve wiring contributes to the overall comfort and lifespan of the system. The correct wiring prevents unnecessary energy waste by ensuring heat is only delivered where and when it’s needed. It also protects the zone valves themselves from potential damage, extending their operational life and reducing the likelihood of needing expensive repairs. In essence, it ensures your heating system functions optimally, saving you money and keeping your home comfortable.

Ultimately, understanding and correctly implementing honeywell zone valve wiring is a crucial aspect of maintaining an efficient and reliable home heating system. By understanding the importance of proper wiring and common misconceptions, you can ensure that your system operates at its best, providing consistent comfort and minimizing energy waste. Correct implementation can prevent various problems ranging from energy waste to fire hazards.

Key Aspects of Honeywell Zone Valve Wiring

Focusing on the essential aspects of honeywell zone valve wiring allows for a deeper understanding of this crucial process. Ensuring each aspect is concise, exploring various dimensions related to this process.

Voltage Compatibility

Voltage compatibility is critical in zone valve wiring, as using the incorrect voltage can result in damage to the valve and potentially the entire HVAC system. Ensure that the voltage of the power source matches the voltage rating of the Honeywell zone valve, which is typically indicated on the valve’s label. Incorrect voltage use can cause premature valve failure or even pose a safety hazard. Always check that the replacement valve is identical to the old valve and rated at the same voltage to avoid any issues.

Wiring Diagram Adherence

Adherence to the wiring diagram is essential for ensuring proper connections and system functionality. The wiring diagram provides a detailed map of the wire connections, indicating which wires connect to which terminals on the zone valve. Deviating from the wiring diagram can lead to incorrect connections, resulting in system malfunctions or even damage to the equipment. If the original diagram is unavailable, locate the online version and follow all instructions closely.

Secure Connections

Secure connections are necessary for preventing loose wires, electrical shorts, and system failures. Always use wire connectors to ensure that the wires are firmly connected to the zone valve terminals. Loose wires can cause intermittent operation, voltage drops, and potential safety hazards. Double-check all connections after completing the wiring to ensure they are tight and secure.

Testing

Testing your work after installation is critical to verify the correct operation of the zone valve and the overall heating system. Use a multimeter to check the voltage at the valve to ensure that the correct electrical signals are being received. Also, check with a second person to turn up the thermostat to make sure the zone valve is actually opening and closing correctly. Also be sure to check all connections and that there are no exposed wires.

The key aspects of honeywell zone valve wiring, through examples, connections, or linkage to the main topic are: voltage, adherence, connection, and testing. By understanding the voltage and testing after connecting all the connection is critical to make sure the zone valve operates normally and correctly.

Honeywell zone valve wiring requires careful attention to detail and the utilization of correct procedures. By understanding the key aspects, technicians and homeowners alike can ensure that the installation or repair process is completed efficiently and safely.

Practical Tips for Honeywell Zone Valve Wiring

Effective honeywell zone valve wiring involves more than just following instructions; it also requires employing practical tips to ensure a reliable and safe installation. These tips cover various aspects, from preparation to troubleshooting, and can significantly improve the overall outcome of the wiring process.

The following tips focus on enhancing safety, accuracy, and longevity when performing honeywell zone valve wiring. By adhering to these guidelines, users can avoid common pitfalls and achieve optimal performance from their zone valve systems.

Double-Check the Wiring Diagram

Before connecting any wires, thoroughly review the wiring diagram specific to your Honeywell zone valve model. Ensure you understand the function of each wire and its corresponding terminal on the valve. This helps prevent misconnections and potential system malfunctions.

Use a Multimeter to Verify Voltage

Before working on any electrical components, use a multimeter to verify that the power is turned off to the circuit. Additionally, use the multimeter to check the voltage levels to ensure they match the valve’s specifications. This prevents electrical shocks and equipment damage.

Label Wires Clearly

When disconnecting wires from the old zone valve, label each wire with its corresponding terminal or function. This makes it easier to reconnect the wires correctly to the new valve, especially if you need to take a break or refer back to the wiring at a later time.

Use Wire Connectors for Secure Connections

Always use wire connectors to ensure secure and reliable connections. Wire connectors provide a tight and insulated connection, preventing loose wires and potential electrical shorts. Avoid simply twisting the wires together, as this can lead to unreliable connections and system failures.

Inspect Wires for Damage

Before connecting the wires, inspect them for any signs of damage, such as cuts, fraying, or exposed conductors. Replace any damaged wires to ensure a safe and reliable connection. Damaged wires can cause electrical shorts and fire hazards.

Take Photos of the Wiring Before Disconnecting

Before disconnecting the wires from the old zone valve, take clear photos of the wiring configuration. This serves as a visual reference that you can refer back to during the reconnection process. This can be especially helpful if you encounter any unexpected issues or need to troubleshoot the wiring.

Test the System After Installation

After completing the wiring, thoroughly test the system to ensure that the zone valve is functioning correctly. Turn on the power and check that the valve opens and closes in response to the thermostat signal. Verify that the zone is heating or cooling as expected. If you encounter any issues, recheck the wiring connections and consult the wiring diagram.

Keep the Area Clean

Ensure the wiring area is neat and clean. This will help the worker in identifying any mistakes while performing the honeywell zone valve wiring. Having clean equipment is also a good measure to protect the tools/equipment from corrosion and malfunction. This may reduce the risk of potential hazards like exposed wires, electrical shock, and damage equipment

Navigating honeywell zone valve wiring can seem complicated, but with the right approach, it becomes a manageable task. The significance of proper wiring lies in its ability to ensure the efficiency and reliability of your heating or cooling system. By carefully following wiring diagrams and taking precautionary steps, it’s possible to maintain an efficient system.

Ultimately, honeywell zone valve wiring is a critical aspect of maintaining an efficient and effective HVAC system. By understanding the proper techniques and safety precautions, homeowners and professionals alike can ensure that these components operate correctly, providing consistent comfort and energy savings. Prioritizing correct wiring will translate to a smoother, more efficient HVAC system.

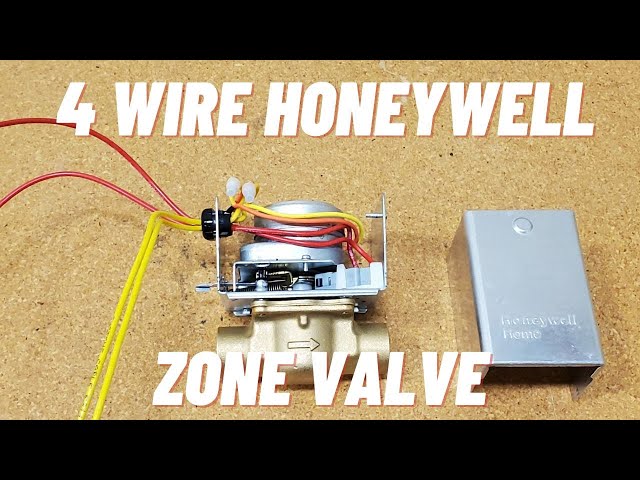

Youtube Video: