Understanding the ethernet cable wiring diagram cat5e is crucial for anyone involved in networking, IT infrastructure, or even setting up a home network. The specific arrangement of wires within a CAT5e cable dictates its functionality and ability to transmit data effectively. A properly wired cable ensures reliable connectivity and optimal network performance. This article will explore the intricacies of the CAT5e wiring diagram, providing a comprehensive guide for understanding and implementing it. By the end, readers will gain a solid foundation in this essential networking concept.

The ethernet cable wiring diagram cat5e refers to the specific pinout configurations used when terminating CAT5e cables with RJ45 connectors. These diagrams define how each of the eight wires within the cable should be arranged and crimped into the connector. There are two main standards for wiring CAT5e cables: T568A and T568B. While both standards achieve the same result, they differ in the specific order of the green and orange wire pairs. It’s vital to consistently use the same standard throughout a network to prevent connectivity issues.

Using the correct ethernet cable wiring diagram cat5e is paramount for maintaining network integrity. Employing an incorrect wiring scheme, even if seemingly functional, can lead to reduced data transmission speeds, increased network latency, and potential network instability. These issues can severely impact productivity and reliability, especially in business environments where consistent and high-speed internet access is critical. Therefore, meticulous attention to detail when following the diagram is a worthwhile investment.

Understanding the T568A and T568B Ethernet Cable Wiring Diagram Cat5e

The T568A and T568B ethernet cable wiring diagram cat5e options often discussed are the two primary wiring schemes for terminating Ethernet cables. This discussion frequently arises in various forums, social media, and even everyday conversations, indicating how relevant this issue is within society. While functionally equivalent for most standard applications, they differ in the arrangement of the orange and green wire pairs. The T568A standard is generally preferred, but T568B remains widely used, especially in older installations.

The critical aspect is ensuring consistency; mixing the two standards within a network can lead to connectivity problems and difficult-to-diagnose issues. When examining the ethernet cable wiring diagram cat5e for T568A, the wire order is as follows: white/green, green, white/orange, blue, white/blue, orange, white/brown, and brown. Conversely, in the T568B standard, the orange and green pairs are swapped: white/orange, orange, white/green, blue, white/blue, green, white/brown, and brown. Careful observation of these diagrams is crucial during cable termination.

Choosing between T568A and T568B ethernet cable wiring diagram cat5e is often a matter of preference or existing infrastructure. In new installations, adhering to T568A is generally recommended to maintain consistency with modern standards. However, in environments where T568B is already prevalent, switching to T568A might necessitate rewiring existing connections, making T568B the more practical choice. Regardless of the chosen standard, adherence to the specific wire order outlined in the diagram is essential for reliable network performance.

Creating a CAT5e Ethernet Cable

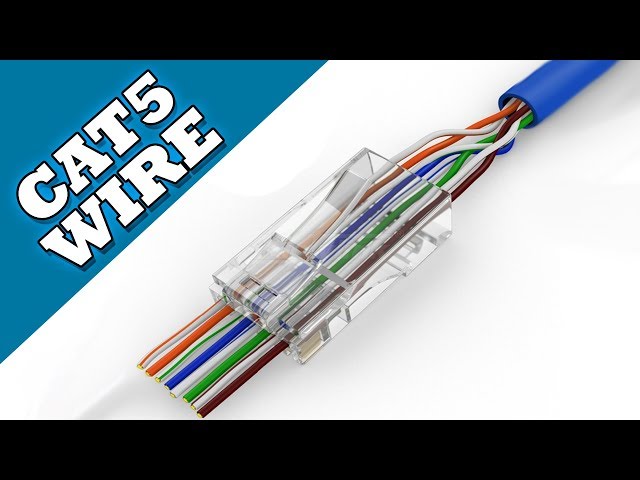

Creating a CAT5e Ethernet cable requires careful attention to detail and precise execution, using the correct wiring diagram. This process involves stripping the cable jacket, arranging the wires according to the chosen standard (T568A or T568B), trimming the wires to the correct length, and crimping them into an RJ45 connector. Each step is crucial for ensuring a reliable and high-performing cable. Using the correct tools and techniques will greatly enhance the success of the process.

Step 1: Gather Your Tools and Materials

Before starting, gather the necessary tools and materials, including a CAT5e cable, RJ45 connectors, a cable stripper, a crimping tool, and a cable tester. Ensure the tools are in good working condition to avoid damaging the cable or connectors. Having the right tools will make the process smoother and more efficient. A cable tester is particularly important for verifying the integrity of the finished cable.

Step 2: Strip the Cable Jacket

Using the cable stripper, carefully remove approximately one inch of the outer cable jacket. Be careful not to nick or cut the insulation of the individual wires inside. Exposing too much wire can lead to signal degradation and reduced performance. A proper cable stripper will allow for precise and consistent jacket removal.

Step 3: Arrange the Wires According to the Wiring Diagram

Untwist the wire pairs and arrange them in the order specified by either the T568A or T568B wiring diagram, depending on the chosen standard. Ensure the wires are aligned neatly and that the insulation is not stripped back too far. Proper wire alignment is critical for ensuring correct pinout configuration. Double-check the wire order before proceeding to the next step.

Step 4: Trim the Wires

Using the crimping tool, trim the wires to an even length, approximately half an inch from the end of the cable jacket. This ensures that the wires will make proper contact with the pins inside the RJ45 connector. Inconsistent wire lengths can lead to poor connectivity and signal loss. A clean, even cut is essential for a reliable connection.

Step 5: Insert the Wires into the RJ45 Connector

Carefully insert the arranged wires into the RJ45 connector, ensuring that each wire is fully seated and reaches the end of the connector. Verify that the wire order is still correct before crimping. Improper insertion can lead to short circuits or open circuits, rendering the cable unusable. Ensure that the wires are properly aligned within the connector channels.

Step 6: Crimp the RJ45 Connector

Place the RJ45 connector into the crimping tool and firmly squeeze the handles until the tool ratchets and releases. This secures the wires within the connector and creates a permanent connection. Insufficient crimping can result in loose connections and intermittent signal loss. A properly crimped connector should be firmly attached to the cable.

Step 7: Test the Cable

Use a cable tester to verify that the cable is wired correctly and that all eight wires are properly connected. The cable tester will indicate any wiring faults, such as crossed wires, short circuits, or open circuits. Testing the cable is crucial for ensuring that it will function correctly in a network. If the cable fails the test, re-crimp the connector or remake the cable.

Frequently Asked Questions About Ethernet Cable Wiring Diagram Cat5e

The ethernet cable wiring diagram cat5e often raises questions regarding its implementation, standards, and troubleshooting. Addressing these common queries can help clarify any confusion and ensure proper cable termination. Understanding the nuances of CAT5e wiring is essential for maintaining network reliability and performance. This section aims to provide concise and informative answers to frequently asked questions.

What’s the difference between T568A and T568B wiring?

The primary difference between T568A and T568B wiring lies in the arrangement of the orange and green wire pairs. In T568A, the green pair is in positions 1 and 2, while the orange pair is in positions 3 and 6. In T568B, this arrangement is reversed. Functionally, both standards are equivalent for most applications, but consistency is crucial within a network. Mixing the two standards can lead to connectivity issues and network instability.

Which wiring standard should I use, T568A or T568B?

The choice between T568A and T568B often depends on existing infrastructure or organizational standards. In new installations, it is generally recommended to use T568A to align with modern standards. However, if an existing network already uses T568B, maintaining consistency by continuing to use T568B may be more practical. Ultimately, the most important factor is consistency across all cable terminations within the network.

What happens if I wire a CAT5e cable incorrectly?

Incorrectly wiring a CAT5e cable can lead to various network problems, including reduced data transmission speeds, increased latency, and intermittent connectivity. In some cases, an incorrectly wired cable may not work at all. It’s crucial to carefully follow the wiring diagram and test the cable after termination to ensure proper functionality. Using a cable tester can quickly identify wiring faults such as crossed wires, short circuits, or open circuits.

Can I use a CAT5e cable for Gigabit Ethernet?

Yes, CAT5e cables are capable of supporting Gigabit Ethernet (1000BASE-T) over shorter distances. While CAT6 or CAT6A cables are generally recommended for Gigabit Ethernet over longer distances due to their improved performance characteristics, CAT5e can still provide reliable Gigabit connectivity in many scenarios. Factors such as cable length and network interference can affect performance.

What tools do I need to make a CAT5e Ethernet cable?

To make a CAT5e Ethernet cable, you will need a few essential tools, including a CAT5e cable, RJ45 connectors, a cable stripper, a crimping tool, and a cable tester. The cable stripper is used to remove the outer jacket of the cable without damaging the inner wires. The crimping tool is used to secure the RJ45 connectors to the cable. The cable tester is used to verify that the cable is wired correctly and functioning properly.

How do I test a CAT5e cable after making it?

After making a CAT5e cable, it is essential to test it using a cable tester to ensure that it is wired correctly and functioning properly. A cable tester typically consists of two units: one that plugs into one end of the cable and another that plugs into the other end. The tester will then send signals through each wire and indicate whether there are any wiring faults, such as crossed wires, short circuits, or open circuits. This ensures the cable will work as expected when connected to network devices.

What is a crossover cable, and when would I use one?

A crossover cable is a type of Ethernet cable that has its transmit and receive wires crossed over, typically by using T568A on one end and T568B on the other. Crossover cables were traditionally used to connect two devices of the same type directly to each other, such as connecting two computers or two switches without using a router or hub. However, modern network devices often support auto-MDI/MDIX, which automatically detects the cable type and adjusts the pinout accordingly, making crossover cables largely obsolete.

The ethernet cable wiring diagram cat5e is not just a technical specification; its the foundation upon which reliable network communication is built. Understanding its intricacies can empower individuals to troubleshoot connectivity issues, create custom network solutions, and ensure optimal performance. A properly wired CAT5e cable is essential for seamless data transfer and uninterrupted network access.

Mastery of the ethernet cable wiring diagram cat5e extends beyond mere knowledge; it fosters confidence in managing and maintaining network infrastructure. Whether setting up a home network or managing a complex enterprise network, a solid grasp of CAT5e wiring principles is invaluable. This knowledge translates to increased efficiency, reduced downtime, and a greater sense of control over network resources.

Key Aspects of the Ethernet Cable Wiring Diagram Cat5e

Focusing on the essential aspects of the ethernet cable wiring diagram cat5e, considering the part of speech of the keyword. Ensuring each aspect is concise, exploring various dimensions related to ethernet cable wiring diagram cat5e as needed based on the part of speech of the keyword. These aspects encompass the underlying principles and practical considerations of cable termination. It provides a structured overview for quick reference and deeper understanding.

Wiring Standards

The T568A and T568B standards define the pinout configurations, dictating the wire order within the RJ45 connector. While functionally equivalent, consistency within a network is paramount. The choice often depends on existing infrastructure or organizational standards. Mixing standards leads to connectivity issues and troubleshooting headaches.

RJ45 Connector

The RJ45 connector is the physical interface used to connect the CAT5e cable to network devices. Proper crimping is essential for a secure and reliable connection. The connector must be correctly aligned and crimped to ensure all eight wires make proper contact. Poor crimping leads to intermittent connectivity and signal loss.

Cable Tester

A cable tester verifies the integrity of the terminated cable, ensuring all wires are properly connected and there are no faults. It identifies wiring issues such as crossed wires, short circuits, and open circuits. Testing is crucial for ensuring the cable will function correctly in a network. A cable tester is an indispensable tool for any network technician.

Gigabit Ethernet

CAT5e cables support Gigabit Ethernet over shorter distances, offering high-speed data transfer. While CAT6/6A are preferred for longer runs, CAT5e remains a viable option for many applications. Factors such as cable length and interference can affect Gigabit performance. CAT5e provides a cost-effective solution for Gigabit networking in many scenarios.

The four key aspects mentioned above highlight the practical considerations of the wiring diagram. T568A/B show the standard, the RJ45 connector facilitates the physical cable, the cable tester is used to ensure if the cable is suitable to use and Gigabit Ethernet describes the cable can be used.

The ethernet cable wiring diagram cat5e is a critical skill in modern networking environments. Understanding the intricacies of wire arrangement, connector types, and testing procedures ensures that network connections are both reliable and robust. In any network installation or maintenance, the diagram functions as a fundamental guide to achieving efficient and dependable communications.

Tips for Successful Ethernet Cable Wiring Diagram Cat5e Implementation

Implementing the ethernet cable wiring diagram cat5e successfully requires attention to detail and adherence to best practices. These tips aim to enhance cable termination skills and minimize potential errors. Following these guidelines ensures reliable network connectivity and optimal performance.

These tips are designed to assist both beginners and experienced professionals in maximizing the effectiveness of the ethernet cable wiring diagram cat5e. From selecting the right tools to maintaining consistent standards, each tip contributes to the overall success of cable termination.

Use Quality Tools

Invest in a high-quality cable stripper, crimping tool, and cable tester. Reliable tools ensure precise and consistent results. Avoid using cheap or damaged tools, as they can damage the cable or connectors. Quality tools make the cable termination process smoother and more efficient.

Choose a Consistent Wiring Standard

Select either T568A or T568B and consistently use the same standard throughout the network. Mixing wiring standards leads to connectivity issues and troubleshooting headaches. Document the chosen standard for future reference. Consistency is key to maintaining a reliable network.

Properly Strip the Cable Jacket

Carefully strip the cable jacket without nicking or cutting the insulation of the individual wires. Damaged insulation can lead to signal degradation and short circuits. Use a cable stripper that is specifically designed for CAT5e cables. Avoid using knives or other sharp objects to strip the jacket.

Align the Wires Neatly

Ensure the wires are aligned neatly and in the correct order according to the chosen wiring diagram. Use your fingers to straighten the wires before inserting them into the RJ45 connector. Misaligned wires can lead to incorrect pinout configurations and connectivity problems.

Trim the Wires to the Correct Length

Trim the wires to an even length, approximately half an inch from the end of the cable jacket. This ensures that the wires will make proper contact with the pins inside the RJ45 connector. Inconsistent wire lengths can lead to poor connectivity and signal loss. Use the crimping tool’s built-in cutter to trim the wires evenly.

Insert the Wires Fully into the Connector

Carefully insert the arranged wires into the RJ45 connector, ensuring that each wire is fully seated and reaches the end of the connector. Verify that the wire order is still correct before crimping. Improper insertion can lead to short circuits or open circuits, rendering the cable unusable.

Crimp the Connector Firmly

Place the RJ45 connector into the crimping tool and firmly squeeze the handles until the tool ratchets and releases. This secures the wires within the connector and creates a permanent connection. Insufficient crimping can result in loose connections and intermittent signal loss. Inspect the crimped connector to ensure that all pins are fully depressed.

Test the Cable Thoroughly

Use a cable tester to verify that the cable is wired correctly and that all eight wires are properly connected. The cable tester will indicate any wiring faults, such as crossed wires, short circuits, or open circuits. Testing the cable is crucial for ensuring that it will function correctly in a network. Retest the cable after making any adjustments.

The ethernet cable wiring diagram cat5e is foundational for establishing robust and reliable network connections. These guidelines aim to equip individuals with the knowledge and skills necessary to tackle CAT5e cable terminations effectively. A meticulous approach ensures that every cable provides optimal performance and minimizes the risk of network disruptions.

By following these tips, both beginners and experienced technicians can enhance their cable termination skills and create high-quality CAT5e cables. A well-executed wiring job translates to a stable and efficient network, contributing to improved productivity and reduced downtime. The ethernet cable wiring diagram cat5e is more than just a technical detail; it is an investment in the long-term health and performance of the network.

In conclusion, mastering the ethernet cable wiring diagram cat5e is essential for anyone involved in network setup and maintenance, guaranteeing reliable and efficient data transmission.

Youtube Video: