Trailer lights and wiring are essential components of any trailer, providing visibility and safety on the road. They consist of a series of lights, reflectors, and electrical wiring that allow the trailer to be seen by other vehicles, both during the day and at night.

Properly functioning trailer lights and wiring not only enhance safety but also comply with legal requirements in most jurisdictions. They enable drivers to communicate their intentions, such as braking, turning, and reversing, to other motorists, thereby reducing the risk of accidents.

When considering trailer lights and wiring, it is important to select high-quality components that are durable and weather-resistant. Regular maintenance and inspection are also crucial to ensure that the lights and wiring remain in good working condition. By adhering to these guidelines, trailer owners can contribute to safer and more efficient road travel.

trailer lights and wiring

Trailer lights and wiring play a crucial role in ensuring the safety and visibility of trailers on the road. Here are seven key aspects to consider:

- Functionality: Essential for signaling intentions (e.g., braking, turning) to other vehicles.

- Visibility: Ensures the trailer is seen clearly, both during day and night.

- Safety: Reduces the risk of accidents by enhancing communication between drivers.

- Compliance: Meeting legal requirements in most jurisdictions.

- Durability: Choosing high-quality components ensures longevity and reliability.

- Maintenance: Regular inspection and maintenance are vital for optimal performance.

- Wiring: Proper wiring is essential for transmitting electrical signals effectively.

These aspects are interconnected and contribute to the overall safety and functionality of trailer lights and wiring. For instance, durable components and proper maintenance ensure the system’s longevity, while visibility and functionality enable effective communication on the road. By understanding and addressing these key aspects, trailer owners can ensure their trailers are equipped with reliable and compliant lighting systems.

Functionality

The functionality of trailer lights and wiring lies in their ability to convey the intentions of the trailer driver to other vehicles on the road. This is achieved through a combination of lights, reflectors, and electrical wiring that allow the trailer to be seen and understood clearly.

- Brake Lights: When the trailer’s brake pedal is pressed, the brake lights illuminate, signaling to following vehicles that the trailer is slowing down or stopping.

- Turn Signals: The turn signals, activated by the driver, indicate the intended direction of the trailer, whether it’s turning left or right.

- Running Lights: Running lights, also known as side marker lights, are positioned at the front and rear of the trailer to increase its visibility, especially during nighttime or in low-light conditions.

- Reflectors: Reflectors are passive devices that reflect light back to its source, enhancing the visibility of the trailer, particularly at night when headlights from other vehicles illuminate them.

These functional components work in unison to ensure that the trailer’s intentions are communicated effectively to other drivers, reducing the risk of accidents and promoting safer road travel.

Visibility

The visibility of trailers is paramount for safety on the road, and trailer lights and wiring play a crucial role in ensuring that trailers are seen clearly by other vehicles, both during the day and at night.

- Enhanced Conspicuity: Trailer lights and wiring make trailers more conspicuous, increasing their visibility to other drivers, reducing the risk of accidents, especially in low-light conditions.

- Daytime Visibility: Running lights, side marker lights, and reflectors contribute to the visibility of trailers during the day, making them more noticeable to other vehicles, even in bright conditions.

- Nighttime Visibility: Headlights, brake lights, and turn signals are essential for nighttime visibility, ensuring that trailers are seen clearly by other drivers, preventing rear-end collisions and other accidents.

- Reflective Surfaces: Reflectors placed on the sides and rear of trailers enhance visibility by reflecting light back to its source, making trailers more noticeable to other vehicles, particularly at night.

The interplay between trailer lights and wiring and visibility is critical for safe road travel. By increasing the conspicuity of trailers, these components help prevent accidents and contribute to the overall safety of all road users.

Safety

The effectiveness of trailer lights and wiring in enhancing communication between drivers is a key factor in reducing the risk of accidents on the road. Proper lighting and wiring enable trailers to convey their intentions and presence to other vehicles, promoting safer driving conditions.

For instance, clearly visible brake lights promptly inform following vehicles of the trailer’s deceleration or stop, allowing them to adjust their speed and maintain a safe distance. Similarly, functional turn signals indicate the trailer’s intended direction, helping other drivers anticipate its maneuvers and avoid potential collisions.

Furthermore, the use of reflectors on trailers enhances their visibility, especially at night. These reflective surfaces bounce back light from headlights, making trailers more noticeable to other vehicles, reducing the risk of rear-end collisions and other accidents.

Overall, the connection between trailer lights and wiring and safety is undeniable. By enhancing communication between drivers, these components play a crucial role in preventing accidents, promoting safer road travel, and protecting both trailer operators and other road users.

Compliance

Trailer lights and wiring are subject to legal requirements in most jurisdictions, ensuring the safety and visibility of trailers on the road. These regulations aim to standardize lighting systems, promote uniformity, and enhance road safety for all users.

- Safety Regulations: Laws and regulations mandate specific lighting requirements for trailers, including the number, placement, and visibility of lights. These regulations aim to ensure that trailers are clearly visible to other vehicles, reducing the risk of accidents.

- Inspection and Enforcement: Many jurisdictions require regular inspections of trailer lights and wiring to verify compliance with legal requirements. Failure to meet these standards can result in fines, penalties, or even the prohibition of trailer operation.

- Insurance Implications: Proper trailer lights and wiring are often a requirement for insurance coverage. Insurance companies may deny claims or limit coverage if the trailer’s lighting system is found to be non-compliant or defective.

- Liability Concerns: In the event of an accident, non-compliant trailer lights and wiring can increase the liability of the trailer owner or operator. Meeting legal requirements helps mitigate these risks.

Compliance with trailer lights and wiring regulations is not only a legal obligation but also a crucial aspect of road safety. By adhering to these requirements, trailer owners and operators contribute to a safer environment for themselves and other road users.

Durability

In the context of trailer lights and wiring, durability is of paramount importance for ensuring the longevity and reliability of these critical components.

- Robust Construction: Durable trailer lights and wiring are constructed using sturdy materials and robust designs. This ensures they can withstand the rigors of road travel, including exposure to weather elements, vibrations, and potential impacts.

- Corrosion Resistance: High-quality components are resistant to corrosion, which can degrade the performance and lifespan of trailer lights and wiring. This is especially important in areas with high humidity or exposure to salt.

- Weatherproofing: Durable trailer lights and wiring are designed to be weatherproof, ensuring they continue to function effectively in rain, snow, and other adverse conditions.

- Quality Assurance: Choosing components that meet industry standards and undergo rigorous testing provides assurance of their durability and reliability.

By investing in durable trailer lights and wiring, trailer owners can minimize the need for frequent repairs or replacements, reducing downtime and enhancing overall safety on the road.

Maintenance

Regular inspection and maintenance are crucial aspects of trailer lights and wiring, ensuring their optimal performance and longevity. Neglecting maintenance can lead to diminished functionality, reduced visibility, and potential safety hazards.

Proactive maintenance involvesof the entire lighting system, including the lights, reflectors, wiring, and connectors. Inspections should focus on identifying any signs of damage, corrosion, or loose connections that may impair the system’s performance. Promptly addressing these issues helps prevent minor problems from escalating into major failures.

also includes cleaning the lights and reflectors to remove dirt, grime, or debris that can obstruct visibility. Additionally, checking the electrical connections and applying dielectric grease to prevent corrosion ensures reliable electrical contact and optimal current flow.

The practical significance of regular maintenance extends beyond ensuring optimal performance. Proper maintenance helps identify and address potential issues before they become safety hazards. For instance, timely detection of loose wiring or damaged reflectors can prevent electrical fires or reduced visibility, minimizing the risk of accidents.

By adhering to a regular maintenance schedule, trailer owners can enhance the reliability and safety of their lighting systems, ensuring that their trailers remain clearly visible on the road, promoting safer driving conditions for all.

Wiring

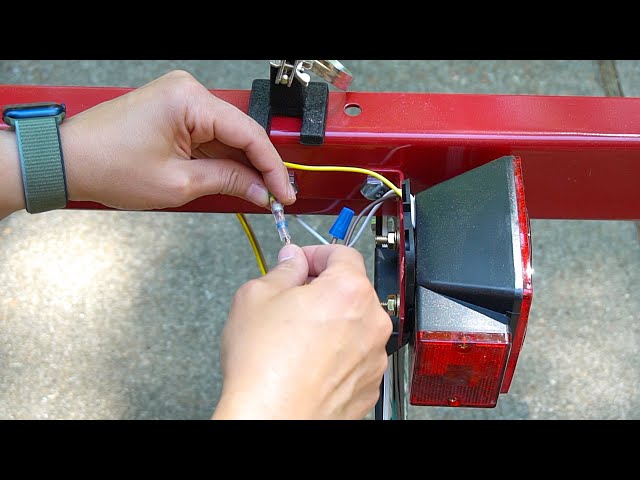

Within the context of trailer lights and wiring, proper wiring serves as the backbone for the entire lighting system, enabling the transmission of electrical signals that power the lights and ensure their functionality.

Adequate wiring involves utilizing wires of appropriate gauge and insulation, ensuring they can handle the electrical load without overheating or causing voltage drop. This is crucial for maintaining the brightness and visibility of the trailer lights.

Furthermore, proper wiring includes secure connections at all junctions and terminals. Loose or corroded connections can lead to intermittent or complete failure of the lighting system, posing safety hazards on the road.

By understanding the importance of proper wiring, trailer owners can appreciate the critical role it plays in ensuring the reliability and effectiveness of their trailer lights and wiring system.

Trailer Lights and Wiring

Trailer lighting systems are essential for ensuring the safety and visibility of trailers on the road. Proper wiring is crucial for transmitting electrical signals effectively, powering the lights, and ensuring their functionality.

Below is a step-by-step guide to creating a wiring diagram for trailer lights and wiring:

- Gather necessary information: Determine the type of trailer, the number and type of lights to be installed, and the location of the power source.

- Plan the wiring layout: Sketch out the layout of the lights and wiring, including the location of the power source, ground connections, and any switches or relays.

- Select appropriate wire gauge: Choose the correct wire gauge based on the amperage draw of the lights and the length of the wire run.

- Connect the wires: Connect the wires according to the wiring diagram, using crimp connectors or solder joints.

- Test the system: Once the wiring is complete, test the system to ensure that all lights are functioning correctly.

By following these steps and adhering to proper electrical practices, you can create an effective and safe wiring diagram for your trailer lights and wiring system.

FAQs on Trailer Lights and Wiring

This FAQ section addresses common questions and misconceptions related to trailer lights and wiring, providing informative answers to enhance understanding and ensure road safety.

Question 1: What are the legal requirements for trailer lights and wiring?

Trailer lights and wiring must comply with regulations set by governing bodies in each jurisdiction. These regulations typically specify the number, placement, and visibility of lights, ensuring uniformity and enhancing road safety.

Question 2: How often should trailer lights and wiring be inspected and maintained?

Regular inspection and maintenance are crucial for optimal performance and safety. Inspections should be conducted periodically to identify any damage, corrosion, or loose connections. Prompt maintenance helps prevent minor issues from escalating into major failures, ensuring the reliability and longevity of the lighting system.

Question 3: Can I install trailer lights and wiring myself?

While it is possible to install trailer lights and wiring yourself, it is generally recommended to seek professional assistance, especially if you lack electrical expertise. Improper installation can lead to safety hazards, decreased visibility, and potential legal issues.

Question 4: What is the best way to troubleshoot trailer light problems?

If you encounter issues with your trailer lights, start by checking the bulbs, fuses, and connections. Ensure that the bulbs are properly seated and not burnt out. Inspect the fuses for any breaks or damage. Tighten loose connections and clean any corrosion. If the problem persists, it is advisable to consult a qualified electrician.

Question 5: How can I prevent corrosion in trailer light connections?

Corrosion is a common problem that can impair the functionality of trailer lights and wiring. To prevent corrosion, apply dielectric grease to electrical connections. This grease acts as a barrier against moisture and prevents oxidation, ensuring reliable electrical contact and optimal performance.

Question 6: What are the safety implications of neglecting trailer lights and wiring?

Neglecting trailer lights and wiring can have severe safety implications. Faulty or non-compliant lighting systems can reduce visibility, making the trailer more difficult to see by other vehicles, especially at night or in low-light conditions. This increases the risk of accidents and poses a danger to both the trailer operator and other road users.

By understanding these FAQs, trailer owners and operators can gain a deeper understanding of the importance of proper trailer lights and wiring, ensuring compliance, safety, and peace of mind on the road.

For more detailed information or assistance with specific trailer lighting and wiring needs, consult the relevant regulations in your jurisdiction or seek professional guidance from a qualified electrician.

Conclusion

Trailer lights and wiring play a critical role in ensuring the safety and visibility of trailers on the road. They enable trailers to communicate their presence and intentions to other vehicles, reducing the risk of accidents and enhancing road safety for all users.

This article has explored various aspects of trailer lights and wiring, emphasizing the importance of compliance with legal requirements, proper installation, regular maintenance, and troubleshooting. By understanding the functionality, durability, and maintenance needs of trailer lighting systems, individuals can ensure the reliability and effectiveness of their trailers on the road.

Youtube Video: